Case

Home / Case / User Manual / Installation and maintenance of float valve

Case

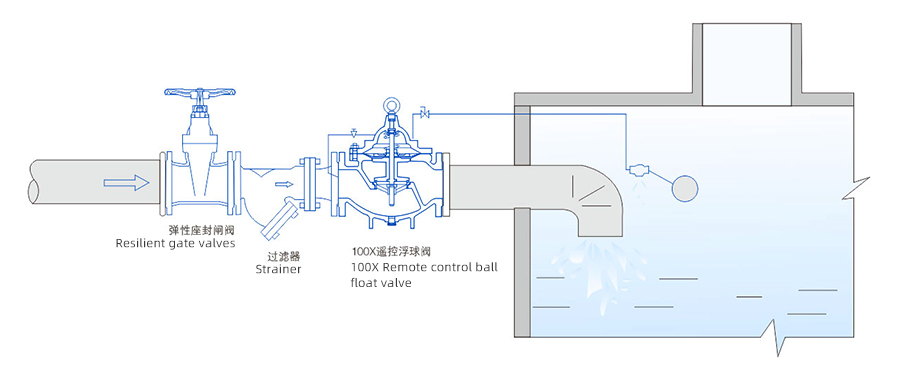

Float ball valve (100X its role and use is to control the water tower and pool of liquid level height, when the water reached the set height, the floating ball jutting, control the floating ball cut-off valve closed, then the valve is closed, stop water supply.

When the liquid level falls back, the float drops, and the stopper valve that controls the float opens, then the valve is in the open state, and the water inlet supplies water to the pool.

Floating ball valve maintenance is simple, convenient debugging, high accuracy of liquid level control, water level is not disturbed by water pressure and tight seal, long service life, floating ball valve can be installed with the height of the pool and the use of space.

1. Before installing the valve, the pipeline should be flushed clean and maintained once or twice a year depending on the water quality.

2. The valve should be installed horizontally (vertical installation please choose vertical main valve).

3. Globe valve or gate valve should be installed in front of the valve for easy maintenance.

4. The main valve and floating ball valve of the valve can be installed as a whole or remotely. The water pipe should be fixed and not subject to vibration.

This valve is installed in the water supply system after debugging. Open the cut-off valve, open the needle valve of the main valve 2 laps to 4 won, the ball threshold is fully open, so that the valve body and upper water chamber full of media after closing the ball valve. Debugging its sealing performance, and then open the ball valve, according to the float liquid level rise and fall, debugging the valve performance.

Disassembly of the main valve :

| Fault phenomenon | The cause of the problem | Elimination method |

| Pool water | 1.Float ball control valve body rubber pad wear, lax sealing2.Leakage in float welds3.The piston of the connecting rod is stuck by a foreign body | 1.Replace gasket to remove debris2.Replace the float ball3.Removal |

| Water level is too low | 1. There is debris in the guide valve body2. The piston of the guide valve connecting rod is stuck3, the import pressure is too low | 1.Remove clutter2.Adjust the3.Adjust the medium pressure |

| Have a sound | 1.There are impurities in the valve body2.Too fast closing speed | 1.Remove impurities2.Reduce the needle valve opening |

This article presented a brief discussion of float valves including the types, applications, and how they work. For more information on related products, consult our other guides.