solution

solution

Power plants are the foundation of modern society, providing electricity to meet the world's power needs. Power plants seeking to increase efficiency are pushing operating temperatures and pressures higher, placing huge demands on the valves, actuators and accessories that must operate continuously, making reliable and low maintenance valves essential to power plant operation.

wesdom manufactures a complete range of high quality, high reliability valves, actuators for a variety of applications designed to provide today's power plants and tomorrow's emerging technologies with reliability and uptime.

In thermal power plants, the main types of valves operated with valve electric devices are gate valves, globe valves, butterfly valves and ball valves.

Gate valves are gate shaped, the gate moves in a straight line in a direction perpendicular to the flow of fluid to cut off or open the flow of fluid, it is the main valve used in thermal power plants on large diameter pipelines (Dg greater than 100mm).

The role of the gate valve is to use the valve flap along the centre of the pathway in the vertical direction of movement to achieve open or close the pipeline pathway. The main opening and closing parts of the gate valve are the valve flap and the valve seat. The construction of the gate valve mainly consists of the valve, valve cover, support, stem, seat, gate and other parts.

Gate valves can be divided into two categories: wedge gate valves and parallel gate valves according to the structural shape of the valve flap.

According to the different movement of the stem when the gate valve opens and closes, the gate valve can be divided into two categories: open stem type and concealed stem type.

The opening and closing parts of the globe valve are plug-shaped valve flaps, which move up and down in a straight line to cut off or open the fluid flow path. It is a valve used more in thermal power plants, Dg in the pipeline below 100mm almost all use the globe valve.

The characteristics and uses of the globe valve: the globe valve is characterised by reliable operation, small opening height, tightly closed, short opening and closing time, easy to adjust or cut off the flow. However, its fluid resistance, open, close force, and with the increase in the cross-sectional area of the channel and rapidly increasing, made of large cross-sectional area of the pathway and very reliable globe valve is very difficult, therefore, the general diameter of the globe valve in the following 200mm, mainly used in steam pipelines, mainly used to cut off the pipeline media. Globe valve has directional, installation must be noted.

The opening and closing part of the butterfly valve is a disc-shaped butterfly plate, which opens and closes the valve by rotating around the shaft inside the seat, the rotation angle of the butterfly plate from fully open to fully closed is usually less than 90 degrees, and the butterfly valve is not suitable for high temperature and high pressure media.

The opening and closing part of a ball valve is a perforated sphere, which rotates on the axis of the centre line of the valve body to cut off or open the passage of fluid flow. Valve from fully open to fully closed, the stem rotation angle of 90 degrees. The ball valve is suitable for high pressure media, but the working temperature has some restrictions.

Regulating valve through the rotation or lifting of the valve flap to change the cross-sectional area of the channel, so as to change the medium flow and pressure of the valve called regulating valve. According to the working principle can be divided into rotary regulating valve and lift regulating valve.

Check valve, also known as check valve or check valve, the main purpose is to automatically close the valve flap by the force of the medium to prevent the backflow of the medium in the pipeline and avoid accidents. It is widely used in all kinds of pump export pipeline, water supply pipeline, steam pumping pipeline, hydrophobic pipeline, and other pipelines that do not allow the backflow of media. According to the structure is divided into lift type, swing type and butterfly type.

The role of traps is to automatically and intermittently remove condensate from steam piping and steam equipment systems and to prevent steam from escaping.

1, We enable the smooth and safe operation of power plants through innovative water treatment and wastewater reuse.

2, WESDOM has built up a reputation as a specialist for valves and solutions in the power plant industry. A wide range of well known and respected customers rely on our knowledge and experience and benefit from our wide range of products.

3, A single power plant uses hundreds of valves to control almost every aspect of its operation.Valves, in conjunction with a controlling actuator, are used for pollution control, feed water, cooling water, chemical treatment, bottom ash and steam turbine control systems.

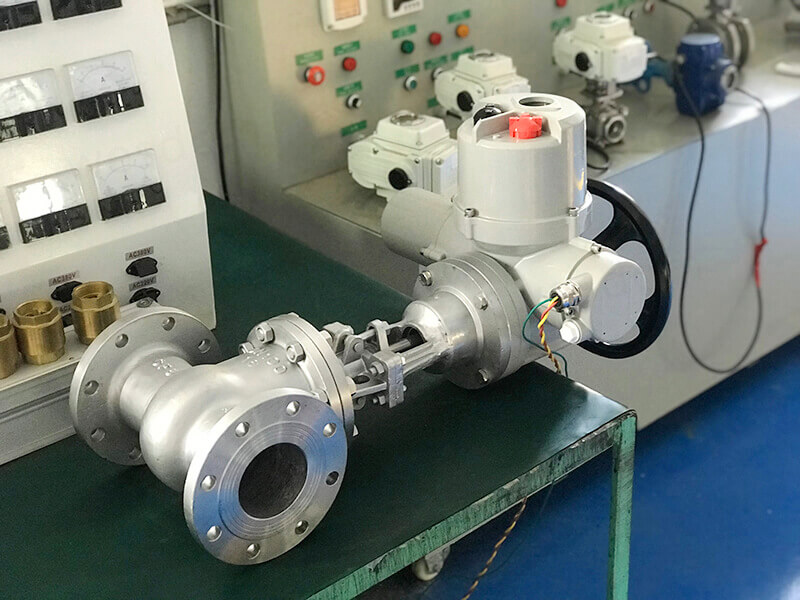

WESDOM electric actuated gate valves are applied in Pakistan power plant.

End user : The Derbeira Hydropower Station

Project No.: OP/ITR-585 & OP/ITR-586

Product: 16” 300lb electric actuated carbon steel gate valve

Email:info@wsdsolution.com

Tel:+86-17319732766