Product

Product

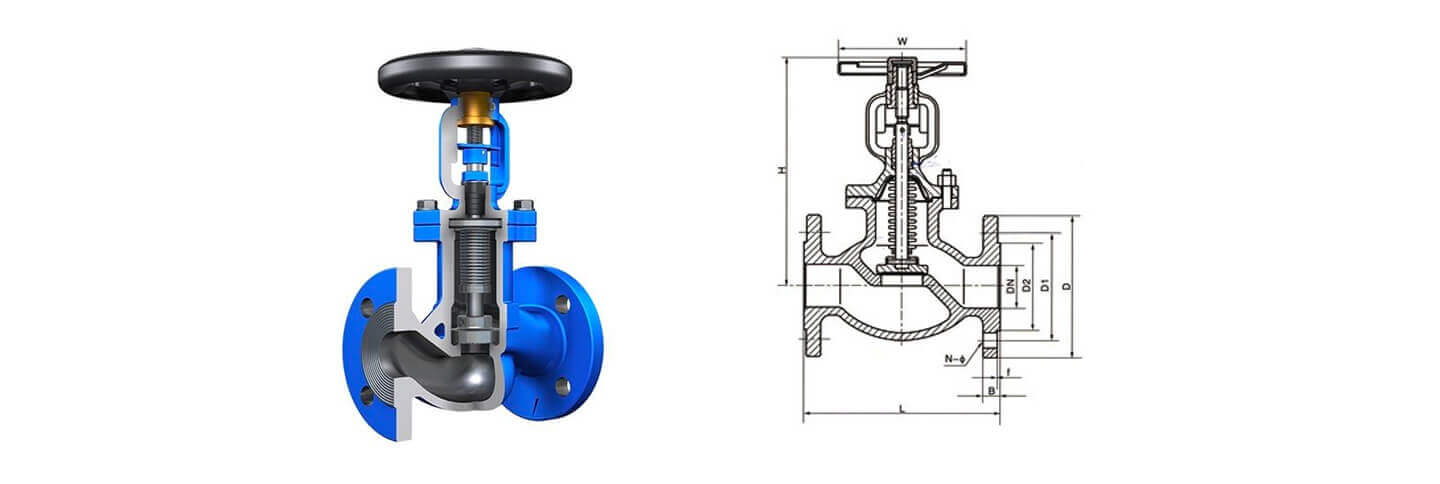

Bellows Globe Valve

Size: 3”~12”

Pressure Rating: PN10,PN16

Material: Gs-c25 、SS304 SS316

Design Standard: DIN EN13709-2003

Inspection Standard: DIN EN12266:2003

Application medium: Gas

Application Temperature: -20℃-425℃

Applied projects: Petrochemical/chemical fiber textile/ plastic paper/electric power steel/printing and dyeing rubber/ natural gas and other gas systems

Products real shot

Application

Bellows Seal Globe Valve,is normally designed and manufactured according to Germany standard and European standard EN13709.as normal,it’s linear motion closing-down valve used to start, stop or regulate the flow using a closure member referred as a disc. the Bellows Seal Globe valves are most suitable and widely used to control or stop the flow of liquid or gas through a pipe for throttling and controlling fluid flow and are generally employed in small size piping.

It was invented to meet strict requirements of tightness and severe working conditions.except for the conventional packing assembly as all the gate valve,the bellows seal globe valve also has a bellow packing device.The accordion-shaped bellows is contained and protected inside the thick metal tube.One end of the bellows is welded to the valve stem, and the other end is welded to the protective tube. With the wide flange of the tube firmly clamped in the bonnet of the valve, a leak-free seal exists.

Bellows have a limited service life, which means the possibility of a rupture is likely. This is why a conventional packing assembly is always included in a bellows-equipped bonnet.So the bellows seal is an extra packing sealing for the gate valves,it’s suitable for some severe working conditions.

One of the most frequent and serious problems valves face is gland leakage, results in wasted and increased plant downtime. Apart from the high cost of energy losses, Gland leakages can also cause serious environmental, ecological and health hazards to plant workers and personnel. Leakage of sensitive material can also constitute to a fire hazard, explosion, or damage to equipment by corrosive material. Air entering the pipeline could produce inflammable explosive or poisonous mixtures. Gland packed valves often demand continual maintenance in accessibility creating particular difficulties. The bellows comply to conditions at high temperatures and are capable of withstanding over 10,000 cycles without failure.

Bellows Seal Globe Valve ls a new kind of globe valves with dual-seal. So its sealing capacity is very good. The sealing surface is bead welding with hard alloy and the stem surface is in ‘nitrogen treatment. Hence, it is the valve of attrition-resistant good anti-corrosion performance and long service life.

Main features of bellows seal globe valve:

In particular chemical processes the fluids in the pipes are often toxic, radioactive and hazardous. Bellows seal globe valves are used to prevent leakage of any toxic chemical to the atmosphere. Body material can be selected from all available materials,The bellow can be supplied in different materials like 316Ti, 321, C276 or Alloy 625.

1).There is wide range of capabilities as available in standard pattern(streght pattern),Angle pattern,and Wye pattern(Y pattern).

2).Metal bellows seals the moving stem and increases durability of packed stem seal valves.

3).Two secondary stem seals: a) Backseat in open position; b) Graphite packing.

4).Bellow-sealed valves are usually leak tested using a mass spectrometer to detect leakage rates below 1x10E-06 std.cc/sec.Double sealing design (bellows seal and stem packing) if the bellows fail, valve stem packing will also avoid leakage,and in conformity with international tightness standards;

5).Easy Machining and resurfacing of the seats,for various purposes.

6).Short travel distance of the disc(stroke) between the open and closed positions,Bellows seal globe valves are ideal if the valve has to be opened and closed frequently;

7).Widely used in all the countries in European union,and some other countries as well.

Production process:

During the production process, castings and cleaning, machining, epoxy coating assembly, pressure testing and storage all processes can ensure product quality.

They are used in industries including oil chemistry, pharmaceuticals, fertilizer and power generation to prevent the backward flux of the media. It is a valve that can realize the open and close according to the force of the working medium.

Pakistan Petroleum Project

Main products:

Bellows Globe Valve and fittings

Project description:

All valves and fittings were through SGS Inspection.

Client feedback:

WESDOM is a very trustworthy team, not only professional, but also caring and enthusiastic in service. If there is a demand in the future, we will choose WESDOM without hesitation.

Project pictures:

Products real shot

Application