Product

Product

D643H Triple Eccentric Butterfly Valve

Size:DN80~DN3200

Pressure Rating: PN10, PN16, CL150, JIS 5K/10K

Material: SS304, SS316

Design Standard: EN 593, MSS SP67, API 609, BS5155

Inspection Standard: API 598, ISO 5208, EN 12266

Application medium: Water, Steam and Oil

Application Temperature:-29 °C to 425°C

Applied projects: Chemical electic power/ Textile/ Food/ Medicine/ Paper

D643H Triple eccentric butterfly valve plate and seal ring with a unique three-eccentric structure, with compact stucture,good cutting performance, long service life and other characteristics, both adjustment and cutting off two functions. Widely used in chemical electic power, textile, food, medicine, paper and other industrial departments and municipal engineering, water plants and other pipelines to tap water, sewage, oil liquid or air, gas, natural gas, water vapor media cut-off or regulation flow control.

Characteristic of D643H Triple Eccentric Butterfly Valve:

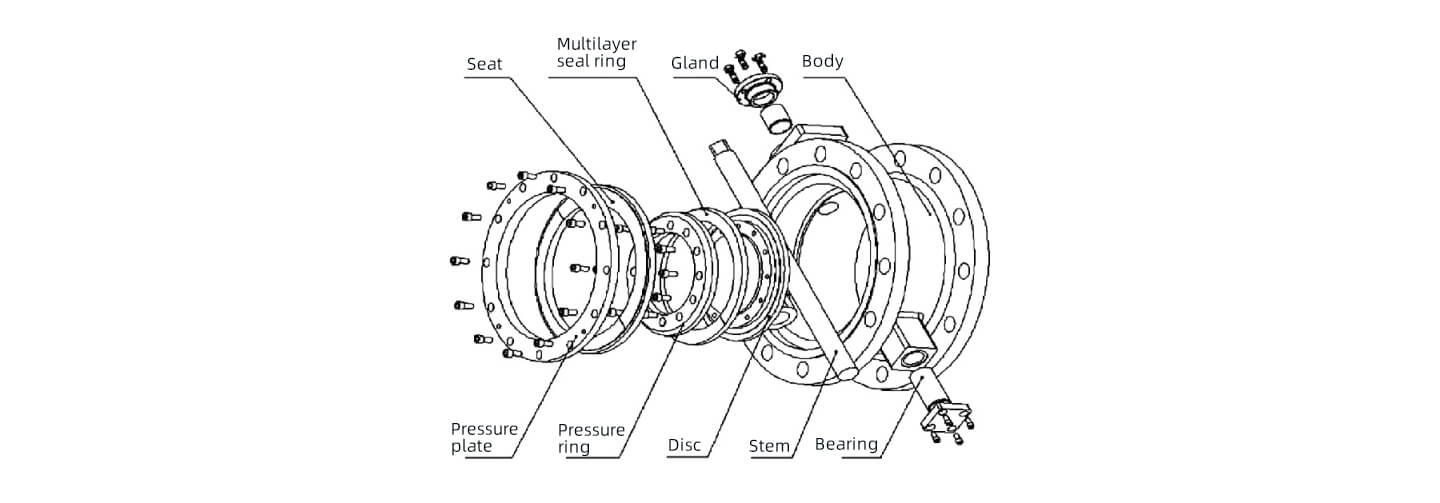

①Body adopts integral casting technology, compact structure, small volume and light weight;

②Disc three ccentic mounting. When closed, disc expands outwards to achieve the best peripheral seal; When opened, disc and seal ring quickly separated, effectively prevent the seal ring wear;

③Sealing ring design is novel, simple and maintenance-free;

④Sealing ring form is multi-level metal hard seal,suitable for harsh working conditions;

⑤Due to the use of three eccentric structure, the operating torque is greatly reduced;

⑥The flow resistance is small, the rated flow coefficient is large, about 3 times that of the same caliber single-seat valve;

⑦Strong self-cleaning ability, long service life;

⑧Standard actuators (pneumatic piston and electric) are interchangeable.

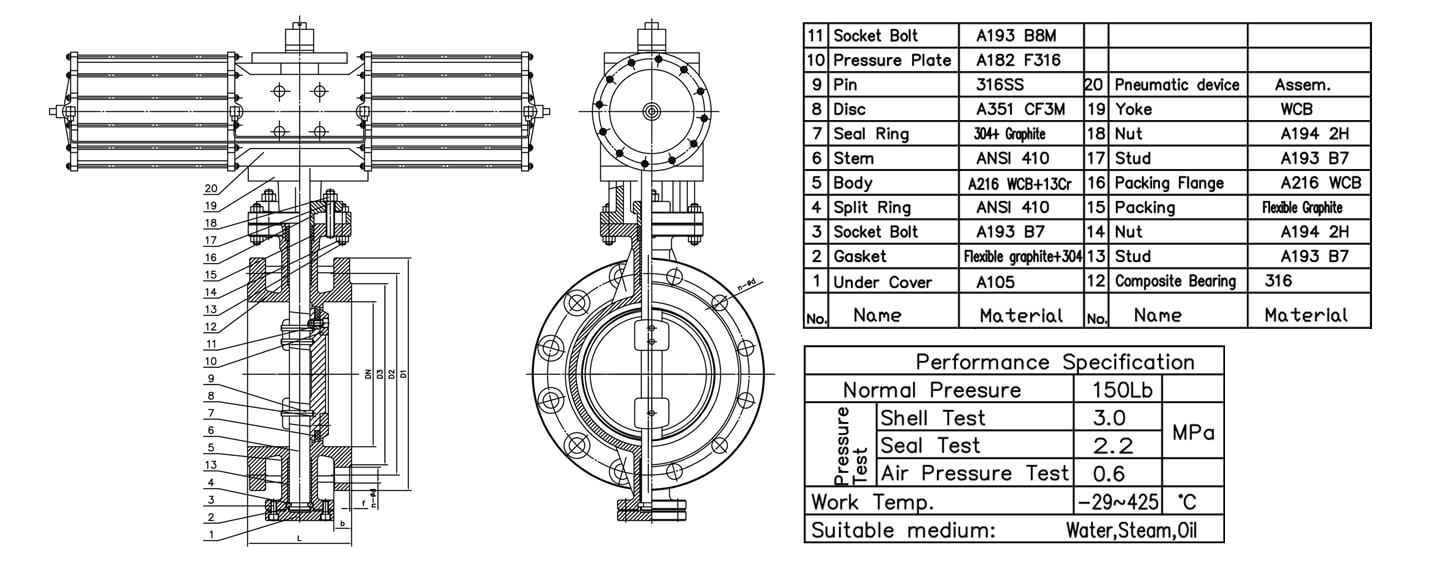

Structure Chart of D643H Triple Eccentric Butterfly Valve:

Basic Structure And Sealing Ring Form:

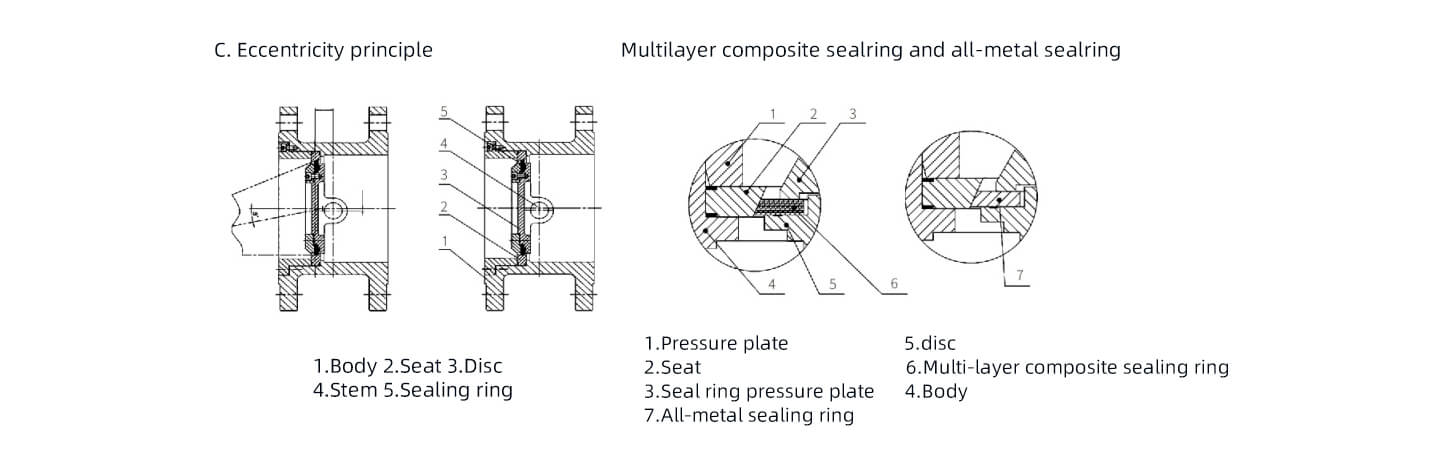

Eccentric butterfly valve design has three eccentricity:

The rotation axis of the valve plate deviates from the cross section center of the sealing surface of the valve plate(H1;

The axis of rotation deviates from the center of the pipe (H2). The rotation axis of the valve seat forms an Angle a ° with the axis of the valve body channel to form three eccentricities.

When it is opened, all points on the sealing surface of the valve plate are separated from the sealing ring at the same time, and there is no extrusion between the valve plate rotation and the sealing ring, which improves the life of the sealing ring. The sealing surtace can be automatically adjusted to maintain the best sealing effect. Multilayer composite sealing ring, leakage level is Vl, zero leakage. When theall-metal sealing ring is used, the leakage grade is V.

Tanzania Water Project

Main products:

Gate Valves, Butterfly Valves, Check Valves, Pipe Fittings, etc.

Client feedback:

The customer sent us the installation pictures of the WESDOM product in the working condition project, and the feedback quality is very good, and will maintain a long-term cooperative relationship with WESDOM;

Project pictures:

Application

The triple eccentric butterfly valve is widely used in metallurgy, electric power, petrochemical, water supply and drainage, and municipal construction and other industrial pipelines with a medium temperature of 425 ℃ or less to adjust the flow rate and load and cut off the fluid.

The maximum pressure rating of the triple eccentric butterfly valve produced by wesdom Valve can reach 2500 pounds, and the standard diameter can reach 120 inches.

The connection mode of the triple eccentric butterfly valve: the clamp, the lug, the flange, the ring connection, the butt welding, the jacket, etc. can be selected, and various structural lengths and standards can be corresponded.

The triple eccentric butterfly valve has a large choice of materials, high and low temperature, and various acids, alkalis and other corrosive media.

Which is widely used in medium temperature under 425°c of metallurgical, power, petrochmical, and municipal construction, drainage and industrial pipe, for regulating traffice and truncated fluid to use.