Product

Home / Products / Butterfly Valve / DN900 Pneumatic Triple Eccentric Hard Seal Butterfly Valve

Product

DN900 pneumatic triple eccentric hard seal butterfly valve

Size: DN80~DN3200

Pressure Rating: PN10, PN16, CL150, JIS 5K/10K

Material: SS304, SS316

Design Standard: EN 593, MSS SP67, API 609, BS5155

Inspection Standard: API 598, ISO 5208, EN 12266

Application medium: Water, Steam and Oil

Application Temperature: -29 °C to 425°C

Applied projects: Chemical electic power/ Textile/ Food/ Medicine/ Paper

Application conditions of triple eccentric hard seal butterfly valve

The triple eccentric hard seal butterfly valve is an industrial valve whose key features lie in the “triple eccentric” design in the structure and the hard seal material used. Compared with traditional soft-sealed butterfly valves, the sealing surface material of hard-sealed butterfly valves is usually metal or carbide, which makes them perform well in harsh working conditions such as high temperature, high pressure, and strong corrosion. The triple eccentric design effectively reduces the wear of the sealing surface when the valve is opened and closed, thereby extending the service life of the valve.

Triple-eccentric butterfly valves are widely used in petroleum, chemical, energy, metallurgy and other industries. Their structure and design allow them to maintain excellent sealing and stability in extreme environments. Triple eccentric butterfly valves are usually used in situations where reliable sealing and durability are required, such as high temperature and high pressure steam pipelines, corrosive media transportation and other fields.

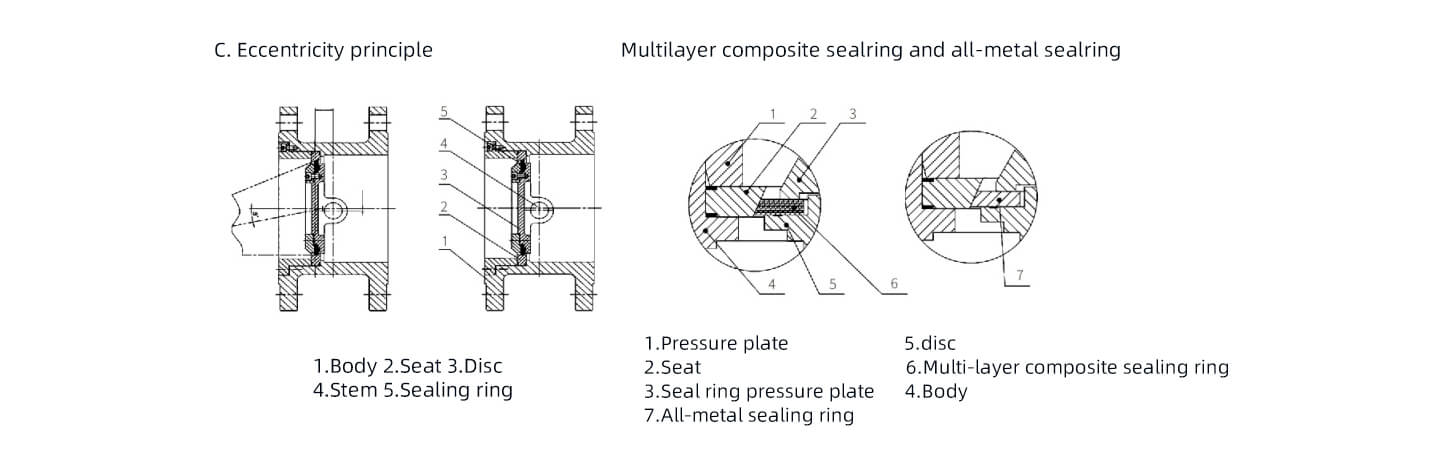

What is the structural principle of the triple eccentric butterfly valve?

The design of the triple eccentric butterfly valve realizes the opening and sealing of the valve through three eccentric positions. These three eccentricities include:

First eccentricity:

The axis of the valve stem deviates from the center of the valve sealing surface, so that when the valve plate rotates, the sealing surface will not directly contact the valve seat, reducing friction.

Second eccentricity:

The valve stem axis deviates from the centerline of the pipe, further reducing the relative movement of the sealing surface during the opening and closing processes.

Third eccentricity:

The centerline of the valve plate sealing surface and the valve seat sealing surface deviate conically. This design ensures that when the valve is close to the closed state, the sealing surface can contact the valve seat smoothly to achieve friction-free sealing. This design not only reduces the wear between the sealing surfaces, but also increases the service life of the valve.

The main advantage of this structure is that when the valve is closed, the contact between the sealing pairs is gentle and will not cause scratches and wear. When it is completely closed, the triple eccentric structure can ensure the self-locking function of the valve and ensure that the medium does not Will leak.

What is the main difference between triple eccentric butterfly valve and double eccentric butterfly valve?

Both double-eccentric butterfly valves and triple-eccentric butterfly valves are widely used in industrial applications, but there are some important differences in the structural design between the two:

The eccentric design is different:

The double eccentric butterfly valve has only two eccentric points, which are the valve stem deviating from the center of the valve plate and the valve stem deviating from the center of the pipe. This causes slight contact between the valve plate and the sealing surface when the valve is opened, causing wear. The triple-eccentric butterfly valve has an additional tapered eccentric point, which further reduces friction when the valve is opened and improves sealing performance.

Difference in sealing performance:

Since the triple eccentric design can provide friction-free sealing when closing, the sealing performance of the triple eccentric butterfly valve is significantly better than that of the double eccentric butterfly valve. When double-eccentric butterfly valves are frequently switched on and off, the sealing surface is prone to wear, while triple-eccentric butterfly valves effectively avoid this problem and are suitable for more demanding working conditions.

Differences in durability and application scenarios:

Double eccentric butterfly valves are more suitable for fluid control under normal temperature and pressure, while triple eccentric butterfly valves can maintain excellent sealing in high temperature, high pressure, and highly corrosive situations, and are suitable for high-pressure steam systems. , chemical equipment and other complex working conditions.

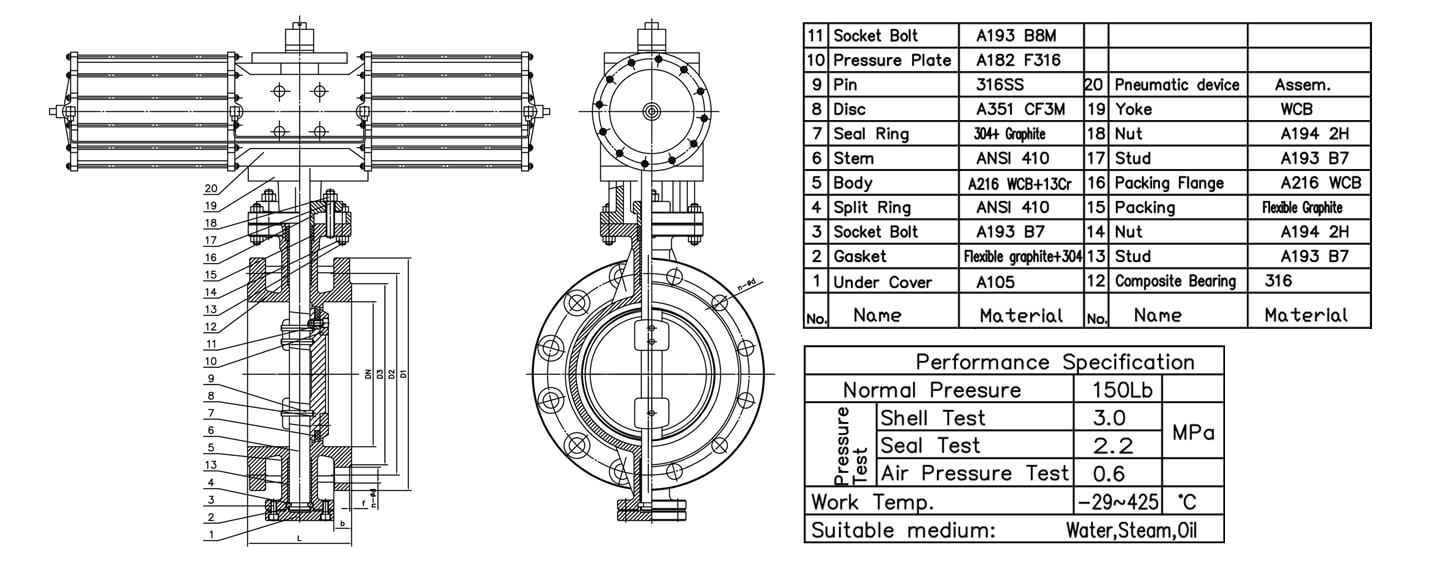

Structure Chart of Triple Eccentric Butterfly Valve:

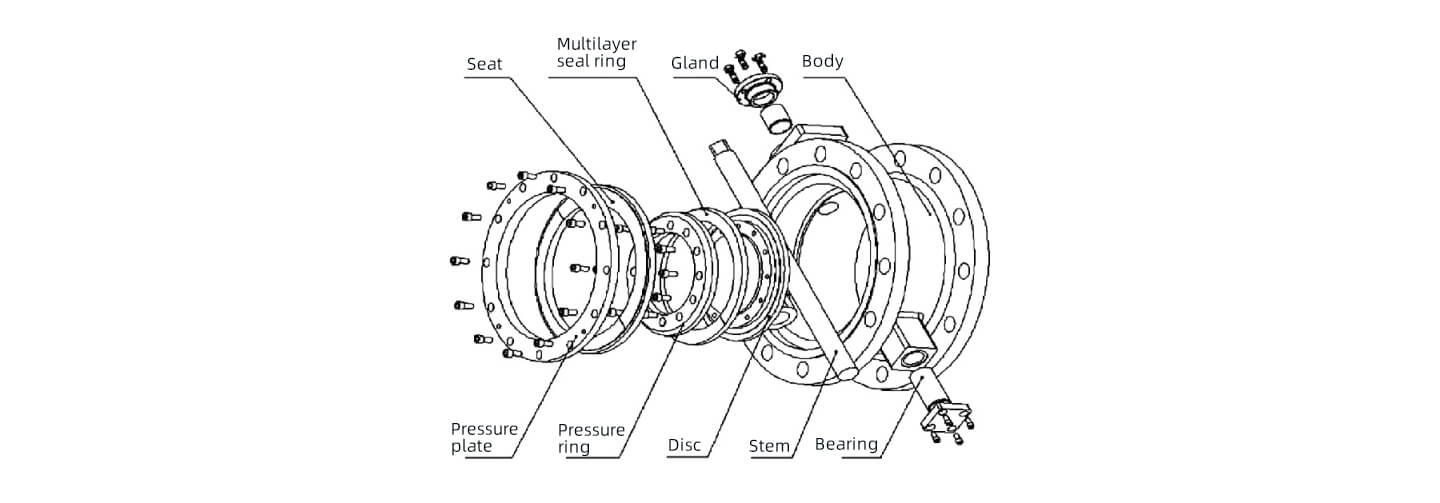

Basic Structure And Sealing Ring Form:

What are the characteristics and biggest advantages of triple eccentric hard seal butterfly valve?

Triple eccentric hard seal butterfly valve has shown many advantages in the industrial field with its unique design and hard material.

Here are its main features and biggest advantages:

Friction-free seal:

Thanks to the triple-eccentric design, the triple-eccentric butterfly valve has almost no friction when opening and closing. This not only extends the life of the sealing surface, but also improves the sealing performance of the valve and avoids common seal failure problems.

High temperature and high pressure resistance:

The sealing material of hard-sealed butterfly valves is usually metal or carbide, which allows it to withstand extreme high temperature and high pressure environments. In contrast, soft-sealed butterfly valves may fail due to aging or deformation of the sealing material at high temperatures, while hard-sealed butterfly valves can continue to work stably under harsh conditions.

Strong corrosion resistance:

Since the sealing material of the triple eccentric butterfly valve can be corrosion-resistant metal or alloy, it is suitable for handling corrosive media, such as acids, alkalis and other chemical substances. Compared with soft-sealing butterfly valves, it is more durable in corrosive media.

Long service life:

The triple eccentric butterfly valve will not fail due to wear when sealing, so it can still maintain a long service life even under frequent opening and closing operations. This is especially important for systems requiring high-frequency operation.

High sealing reliability:

The triple eccentric design allows the sealing surfaces of the butterfly plate to automatically come together when closing, achieving a self-locking function and ensuring no leakage of media. This design greatly improves the sealing reliability of the valve and is especially suitable for working conditions requiring zero leakage.

Turkey Project Case

Project Name: Turkey plant project

End User: International Investment Company

Supply Products: From DN300 to DN900 Electric Butterfly Valves

Contract Amount: USD 370,000

Project overview

The end user of this project is an international investment company, a large-scale industrial project located in Turkey. The core equipment requirement of this project is a pneumatic hard-sealed triple-eccentric butterfly valve for factory process control, with specifications ranging from DN300 to DN900. These pneumatic hard-sealed triple-eccentric butterfly valves will serve as key components for fluid control in factory piping systems. WEIZIDOM successfully won this project with a total contract value of US$370,000.

What can you get by choosing WEIZIDOM?

Choosing WEIZIDOM as a supplier not only means getting high-quality products, but also means getting the following multiple guarantees:

1. First-class product quality: WEIZIDOM is famous for its excellent product quality in Pakistan, Philippines, Malaysia, Indonesia, the United States, Mexico, Togo, Morocco, Saudi Arabia, Malawi and other countries. Its products have undergone strict quality testing and comply with international standards, ensuring long-term and stable operation.

2. Professional technical support: From project start to equipment put into operation, WEIZIDOM’s technical team always provides all-round support. Whether it is on-site installation guidance or remote debugging, WEIZIDOM ensures that customers can receive professional technical services at any time.

3. Flexible delivery and service arrangements: In terms of delivery time, WEIZIDOM has demonstrated extremely high flexibility and can adjust production plans according to the urgency of the project to ensure on-time delivery of products. In addition, WEIZIDOM offers several years of warranty service and is always ready to provide necessary after-sales support.

4. Global project experience: WEIZIDOM has rich experience in international project execution and can quickly adapt to project management needs in different regions. Whether working with multinational teams or communicating with customers from different cultural backgrounds, WEIZIDOM can handle it with an efficient and professional attitude.

For this Turkish factory project, WEIZIDOM successfully won the contract with its high-quality products, flexible solutions and professional project execution capabilities, and set another example in the international market. When you choose WEIZIDOM, you can not only get the highest quality products, but also enjoy comprehensive technical support and service guarantee. For future cooperation, WEIZIDOM will continue to bring greater value to customers with excellent quality and service.

Application conditions of triple eccentric hard seal butterfly valve

Due to its excellent sealing performance, high temperature resistance, corrosion resistance and long life, triple eccentric hard seal butterfly valve is suitable for various extreme and harsh industrial conditions.

Specific application conditions include but are not limited to:

High temperature and high pressure environment:

Triple eccentric hard seal butterfly valve can withstand high temperatures up to hundreds of degrees Celsius, and is suitable for high-pressure pipeline systems, such as steam pipelines and boiler systems in power plants.

Corrosive medium transportation:

In the chemical and petrochemical industries, the medium may be highly corrosive. The triple-eccentric hard-seal butterfly valve can use corrosion-resistant metal sealing materials to ensure that it will not fail after long-term use. It is often used in acid, alkali and salt solution transportation pipelines.

Occasions to prevent medium backflow:

Due to its zero leakage characteristics, triple eccentric hard-seal butterfly valves are often used in systems that require the medium to not flow back, such as oil and natural gas transmission pipelines.

High-frequency opening and closing operations:

In situations where frequent opening and closing is required, such as emission control in sewage treatment systems, the triple-eccentric hard-seal butterfly valve can greatly reduce maintenance frequency and costs with its long life and anti-wear performance.

Harsh hydraulic conditions:

Triple eccentric hard-seal butterfly valves can also provide reliable sealing effects when handling high-speed fluids or fluids with particles, so they are widely used in hydraulic regulating equipment in water conservancy projects.