Product

Product

Eccentric soft sealing butterfly valve

Size:DN100~DN1600

Pressure Rating:PN10, PN16, CL150, JIS 5K/10K

Material:SS304, SS316

Design Standard:EN 593, MSS SP67, API 609, BS5155

Inspection Standard:API 598, ISO 5208, EN 12266

Application medium:water, oil and gas

Application Temperature:-10 °C to 150°C

Applied projects:Petroleum/ Electricity/ Metallurgy/ Water/ Sewage/ Energy/ Construction

Double eccentric butterfly valve Product description

Flange butterfly valve, mounting between flanges PN10/PN16/A150, with gear box.

The range of WESDOM valves can be used for overground installation, in valve chambers and buried systems.butterfly valves in a range of DN 150 to 2000 mm and PN 10, 16 and 25 bar have been designed to isolate the flow of fluid in:

(1)potable water supply pipelines and treatment plants.

(2)transportation of filtered and recycled water.

(3)irrigation distribution networks.

(4)water-pumping stations and hydroelectric plants.

(5)reservoirs.

The range of WESDOM valves can be used for overground installation, in valve chambers and buried systems. It includes a full range of operating accessories and actuators.

WESDOM valves are installed all over the Asia,Africa continent, the Middle East and throughout Europe. They have justifiably acquired a faultless reputation for their durability, reliability and quality worldwide.

Advantages:

(1)Safe disc and shaft connection

The disc and shaft are connected by means of a key and a keyway. The key is secured with two set screws to prevent fluttering caused by flow velocity and necessary play in the key and keyway connection. In the large dimensions the disc is secured with two stainless steel drive dowels, with key and keyway as back-up.

(2)Two seat designs

The integral seat design has a machined and epoxy coated ductile iron seat integrated in the body. The stainless steel seat design has a replaceable seat ring of stainless steel sealed with an O-ring to avoid leakages under the seat ring.

(3)Disc seal optimised for high performance

The disc seal is shaped to secure fixation in correct position providing a very reliable function. The excellent rubber quality makes it possible to reduce the amount of rubber which ensures low closing torques. The EPDM sealing is approved by DVGW, KIWA and WRAS.

(4)Shaft design features

The shaft sealing is replaceable under pressure to enable easy maintenance. Sealings of EPDM secure tightness from inside and out, and NBR sealings protect against impurities and fluids from outside.

The butterfly valves are optionally available with a locking device which makes it possible to lock the disc in open/closed position if gearbox replacement becomes necessary.

The low friction PTFE bearings ensure low operating torques and the protected shaft ends secure durability since there are no uncoated ductile iron surfaces exposed to the media.

(5)Bi-directional and slim design

The valves are bi-directional even though valves from DN700 and up are marked with an arrow indicating the preferred flow direction. We have also minimised the weight to make handling easier and to put less strain on the environment.

(6)Actuation of your choice

We offer any type of actuation. Our standard options are IP67 gearboxes with handwheel for above ground installation, IP68 gearboxes for buried service, and ISO-input gearboxes for mounting of electrical actuators.

Features & Benefits:

①Simple structure, good interchangeability, and low price.

②The stem seal is not easily deformed to avoid the normal stem leakage, and the overall support is good, stable and firm.

③With less seat rubber, there is less potential for expansion and it is easier to control the torque within the proper range.

④The use of two-piece valve stems with no pin connection, the structure is simple and compact, and mainte颅nance and disassembly are very convenient.

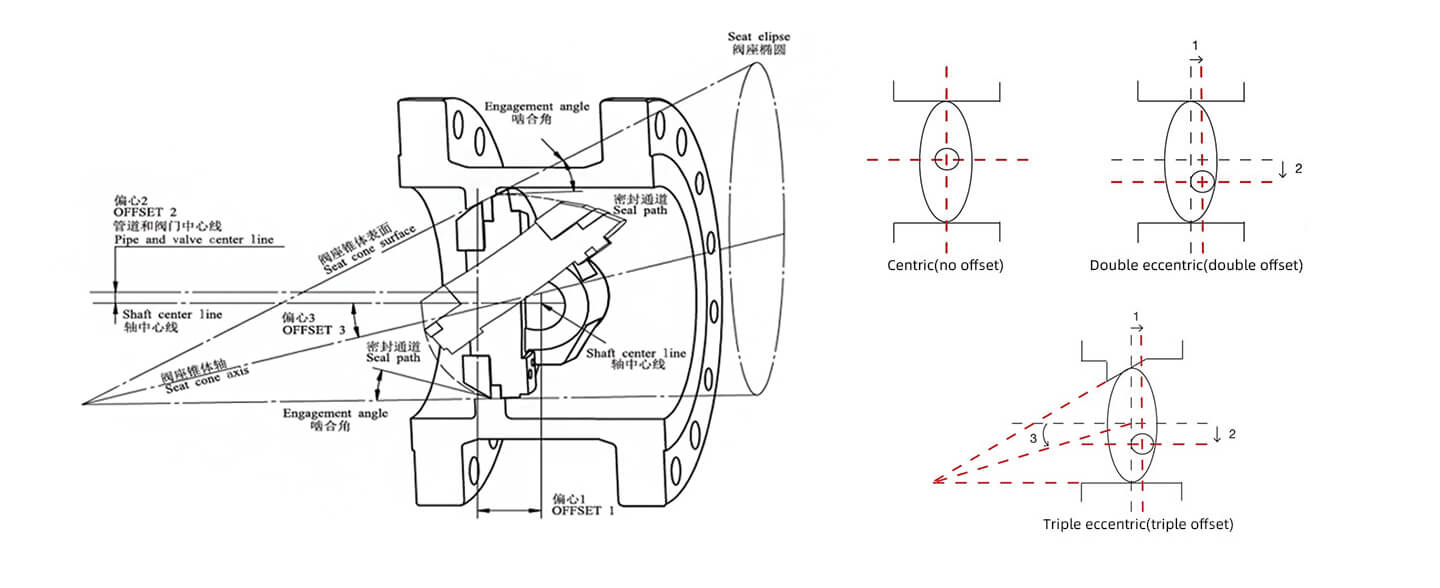

Wesdom butterfly valve has the ideal sealing track on basis of following three-eccentric principle without friction and interference between sealing sets and also adopts the proper material, which make the butterfly valve have the reliable sealing ability corrosion resistant,temperature resistant, and wearing resistance.

The main features as bellow:

1.Small open torque flexible, convenient, labor saving and energy economized.

2.Three-eccentric structure to make the disc more and more tighter, with reliable sealincability and no leakage.

3.High pressure resistant, corrosion resistant.

4.Wesdom triple eccentric butterfly valve has New structure design body.

5.The new triple eccentric structure design achieves zero friction, more stable performance and longer sealing life.

6.Through ingenious design, the butterfly valve can be flexibly opened and closed from low temperature to high temperature, with excellent sealing performance, fully meeting the sealing standard of zero leakage of the valve under severe working conditions.

7.triple eccentric butterfly valvecan achieve a uniform compression sealing effect around the entire valve seat.

| DN | L | PN6/PN10/PN16 | PN6 | ||||||||

| H1 | H2 | H3 | L1 | L2 | L3 | D | D1 | d | n-do | ||

| 100 | 127 | 310 | 109 | 242 | 52 | 45 | 210 | 210 | 170 | 144 | 4–19 |

| 150 | 140 | 440 | 143 | 340 | 52 | 45 | 210 | 265 | 225 | 199 | 8–19 |

| 200 | 152 | 510 | 182 | 410 | 77 | 63 | 315 | 320 | 320 | 254 | 8–19 |

| 250 | 165 | 565 | 219 | 445 | 77 | 63 | 315 | 375 | 375 | 309 | 12–19 |

| 300 | 175 | 630 | 244 | 482 | 95 | 72 | 242 | 440 | 440 | 369 | 12–23 |

| 350 | 190 | 715 | 283 | 565 | 110 | 91 | 275 | 490 | 490 | 413 | 12–23 |

| 400 | 216 | 750 | 312 | 600 | 220 | 91 | 275 | 540 | 540 | 463 | 16–23 |

| 450 | 222 | 820 | 344 | 670 | 147 | 147 | 420 | 595 | 595 | 518 | 16–23 |

| 500 | 229 | 845 | 381 | 695 | 147 | 147 | 420 | 645 | 645 | 568 | 20–23 |

| 600 | 267 | 950 | 451 | 780 | 533 | 179 | 476 | 755 | 755 | 667 | 20–26 |

Main design of butterfly valves:

The butterfly valve can be centric or eccentric. On a centric (concentric) butterfly valve the stem is centered in the middle of the disc and the disc centered in the bore. The eccentric butterfly valve has one or more stems (stub shafts) located offset from the center according to the categories of double and triple offset valves.

In September 2018, wesdom Armaturen delivered six double eccentric butterfly valves series 756 in dimensions DN1000 and DN800 for the supply line from the water reservoirs to the clean water pump stations of the Walddörfer Waterworks in Hamburg.

We offer double eccentric butterfly valves in DN150-2800 designed with durability in focus. The tilted and firmly secured disc, the optimised seal design and the corrosion protected shaft end zones are all features that exceed the market standards.

Project pictures:

The butterfly plate must be in the closed position during installation to ensure that the butterfly plate does not collide with the pipe flange.

Application

Butterfly valves can be used for a broad range of applications within water supply, wastewater treatment, fire protection and gas supply, in the chemical and oil industries, in fuel handling systems, power generation etc. Some of the advantages for this type of valve are the simple construction not taking up too much space, and the light weight and lower cost compared to other valve designs.