Product

Product

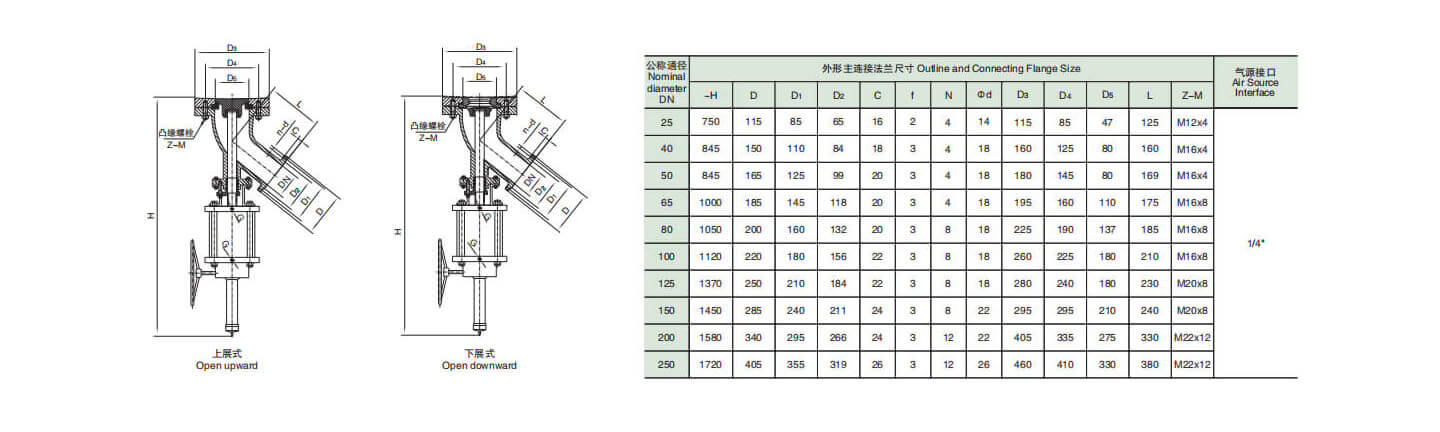

Pneumatic Discharge Valve Control valve

Size: 2”~20”

Pressure Rating: PN10-PN40,150LB-300LB

Material: Carbon Steel Stainless Steel

Design Standard: API6D,GB/T12237

Inspection Standard: API598,GB/T13927

Application medium: water, oil, powder

Application Temperature: 0-200℃

Applied projects: Pneumatic feeding valve is widely used in natural gas, oil products, chemical, metallurgy, paper making, power, mining, printing and dyeing, biological pharmaceutical, daily chemical, food and beverage, water treatment and air treatment and other industries of fluid automatic control or regulation control, and automatic pneumatic instrument matching use.

Features:

(1)Pneumatic discharge valve is installed at the bottom of vessel, reaction kettle and storage tank.

(2)It is used for sampling, material layout, material feeding and turning off no dead zone.

(3)It simultaneously removes residues at the bottom of the container.

(4)Disc consists of uplifting&dropping type which means upward type & downward type.

(5)The difference is that the disc of upwar type goes upward to discharge material and downward type goes down to discharge material.

(6)It can also be customized plunger type structure according to working condition requirements.

(7)Pneumatic discharge valve is widely used in high viscosity liquid containing fiber fluid ,easily crystallized fluid ,sedimentary fluid , particle fluid and so on.

(8)It’s specially used for discharging material at the bottom of storage tank and reaction kettle.

(9)That’s why it’s also named bottom kettle valve.

Typical characteristic:

(1)Simple structure , sensitive and reliable action, easy and convenient replacing of disc and sealing ring;

(2)Inverted installation,approximate linear flow path, small flow resistance, no dead corner&small pressure drop loss ;

(3)Sealing surface is overlaying stellite alloy. It’s wear-resisting, corrosion-resisting and high temp resistance. Suitable for harsh environment, such as high temperature and medium containing solid particles;

(4)Sealing surface is machined precisely. Leakage level is above level IV.Soft sealing can reach zero leakage;

(5)Diaphragm type,plunger pneumatic actuator and limit switch can be chosen according to the requirement;

Production process:

During the production process, castings and cleaning, machining, epoxy coating assembly, pressure testing and storage all processes can ensure product quality.

Application

They are used in industries including oil chemistry, pharmaceuticals, fertilizer and power generation to prevent the backward flux of the media. It is a valve that can realize the open and close according to the force of the working medium. So there is no driving method.