Product

Product

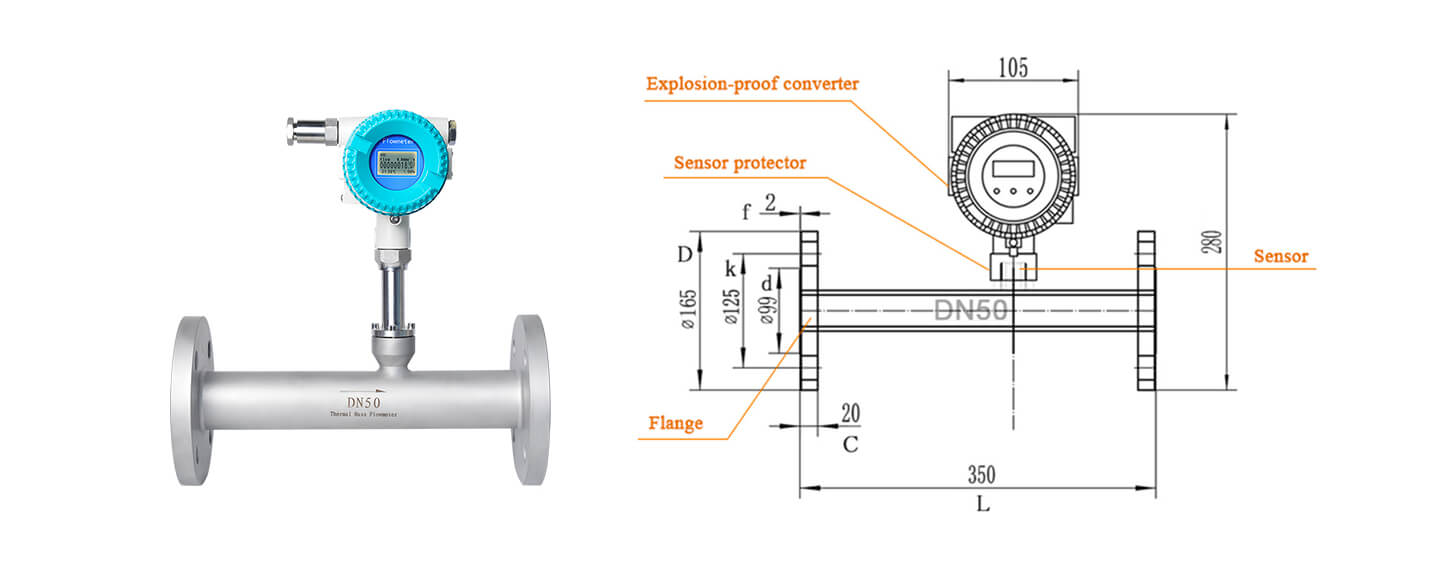

Flange Thermal Gas Mass Flow meter

Size: (Insert connection) DN50-DN2000mm ,In-line connection(DN10-DN2000mm)

Pressure Rating:Insertion type ≤1.6Mpa / Flange type ≤4.0Mpa

Material:SS304(Standard), SS316(Optional)

Design Standard: IP65, IP68

Inspection Standard:IP65, IP68

Application medium:Various of Gas (Except acetylene)

Velocity: 0.1-100Nm/s

Accuracy: +/-1~2.5%

Working Temperature: Sensor:-40~+220 degC Transmitter:-20~+45 degC

Applied projects:Widely used for water supply, non conductive liquids such as distilled water, food oil, light oil, boiler fuel oil engine for diesel measurement, and air conditioner system to measure the flow & heat, food and beverage, pharmaceuticals, ballast water, fuel consumption and other processes on-board ships, etc.

Introduction:

Flange thermal gas mass flow meter is one of kind mass flow meter which is popular in industrial applications is the way they are designed and built. The feature is no moving parts, nearly unobstructed straight through flow path, require no temperature or pressure corrections and retain accuracy over a wide range of flow rates. Straight pipe runs can be reduced by using dual-plate flow conditioning elements and installation is very simple with minimal pipe intrusions.

Flange thermal gas mass flow meter size from DN10~DN2000mm

Features:

(1)Four types of connection;

(2)Easily installation,Simple maintenance, Bidirection testing,Anti Vibration;

(3)Wide flow ratio 100: 1;

(4)Dual Power Supply/More options in the wiring process;

(5)Large diameter small flow rate measurement,can be used for leak detection;

(6)Can measure the mass flow directly,no need temperature and pressure compensation;

(7)Thermal Gas Mass Flow Meter Dimension.

Flange thermal gas mass flow meter advantanges :

(1)Wide range ratio 1000:1;

(2)Large diameter, low flow rate, negligible pressure loss;

(3)Direct mass flow measurement without temperature and pressure compensation;

(4)Very sensitive for low flow rate measurement;

(5)Easy to design and select, easy to install and use;

(6)Suitable for all kinds of single or mixed gas flow measurement Could measure gas with flow velocity from 100Nm/s to 0.1Nm/s, which can be used for gas leak detection;

(7) The sensor has no moving parts and pressure sensing parts, and is not affected by vibration on the measurement accuracy. It has good seismic performance and high measurement reliability;

(8) No pressure loss or very small pressure loss;

(9) When measuring the gas flow, it is often expressed in the volume flow unit under the standard state, and the medium temperature/pressure change hardly affects the measured value. If the density is constant in the standard state (that is, the composition is unchanged), it is similar to a mass flow meter;

(10) Support multiple communication methods, such as RS485 communication, MODBUS protocol, etc., which can realize factory automation and integration;

Flange thermal gas mass flow meter installation:

① Observe the recommended inlet and outlet requirements.

②Good engineering practice is necessary for the associated pipe work and installation.

③ Ensure correct alignment and orientation of the sensor.

④ Take measures to reduce or avoid condensation (e.g. install a condensation trap, thermal insulation, etc.).

⑤ The maximum permitted ambient temperatures and the medium temperature range must be observed.

⑥ Install the transmitter in a shaded location or use a protective sun shield.

⑦ For mechanical reasons, and in order to protect the pipe, it is advisable to support heavy sensors.

⑧ No installation in where large vibration exists

⑨ No exposure in the environment containing a lot of corrosive gas

⑩ No sharing power supply with frequency converter, electric welding machine and other machines which can make power-line interference.

Daily maintenance for flange thermal gas mass flow meter:

In the daily operation of the thermal gas mass flowmeter, check and clean the flowmeter, tighten the loose parts, find and deal with the abnormality of the flowmeter in operation in time, ensure the normal operation of the flowmeter, reduce and delay the wear of components, Extend the service life of the flowmeter.

Some flowmeters will become fouling after being used for a period of time, and it must be cleaned by pickling etc. depending on the degree of fouling

Technical Data:

Flange Thermal Gas Mass Flow Meter Parameter:

| Measuring Medium | Various of Gas (Except acetylene) |

| Pipe Size | (Insert connection) DN50-DN2000mm ,In-line connection(DN10-DN2000mm) |

| Velocity | 0.1-100Nm/s |

| Accuracy | +/-1~2.5% |

| Working Temperature | Sensor:-40~+220 degC Transmitter:-20~+45 degC |

| Working Pressure | Insertion Sensor:medium pressure ≤1.6Mpa

Flanged Sensor:medium pressure ≤4.0Mpa Special pressure please double check |

| Power Supply | Compact type: 24VDC or 220VAC, Power consumption ≤18W

Remote type:220VAC,Power consumption ≤19W |

| Response Time | 1s |

| Output | 4-20mA(optoelectronic isolation,maximum load 500Ω),Pulse RS485(optoelectronic isolation) and HART |

| Alarm Output | 1-2 line Relay, Normally Open state, 10A/220V/AC or 5A/30V/DC |

| Sensor Type | Standard Insertion, Hot-tapped Insertion and Flanged |

| Construction | Compact and Remote |

| Pipe Material | Carbon Steel, Stainless Steel,Plastic etc. |

| Display | 4 lines LCD Mass flow, Volume flow in standard condition, Flow totalizer, Date and Time, Working time, and Velocity, etc. |

| Protection | IP65 |

| Nominal dia. | Flange outer dia. | Center hole | Bolt hole | Screw | Sealing surface | Flange thickness | Installation length | |

| DN | D | K | n x L | d | f | C | L | |

| 15 | 95 | 65 | 4×14 | M12 | 46 | 2 | 14 | 280 |

| 20 | 105 | 75 | 4×14 | M12 | 56 | 2 | 16 | 280 |

| 25 | 115 | 85 | 4×14 | M12 | 65 | 2 | 16 | 280 |

| 32 | 140 | 100 | 4×18 | M16 | 76 | 2 | 18 | 350 |

| 40 | 150 | 110 | 4×18 | M16 | 84 | 2 | 18 | 350 |

| 50 | 165 | 125 | 4×18 | M16 | 99 | 2 | 20 | 350 |

| 65 | 185 | 145 | 4×18 | M16 | 118 | 2 | 20 | 400 |

| 80 | 200 | 160 | 4×18 | M16 | 132 | 2 | 20 | 400 |

| 100 | 220 | 180 | 4×18 | M16 | 156 | 2 | 22 | 500 |

Flow Meter project – Pakistan

Portable ultrasonic flow meter is used in temporary on-site measurement of different pipelines throughout the project.

Applicatipn

Thermal gas air flow meter widely use for Electric power, Petrochemical industry, Glass, Ceramics and Building materials industry, and mainly be used to meausre Dry gas, such as Air, Natural gas, LPG gas, Biogas, ect. But thermal gas mass flow couldn’d be used to measure Vapour, Humidity gas and Ethyne.