Product

Product

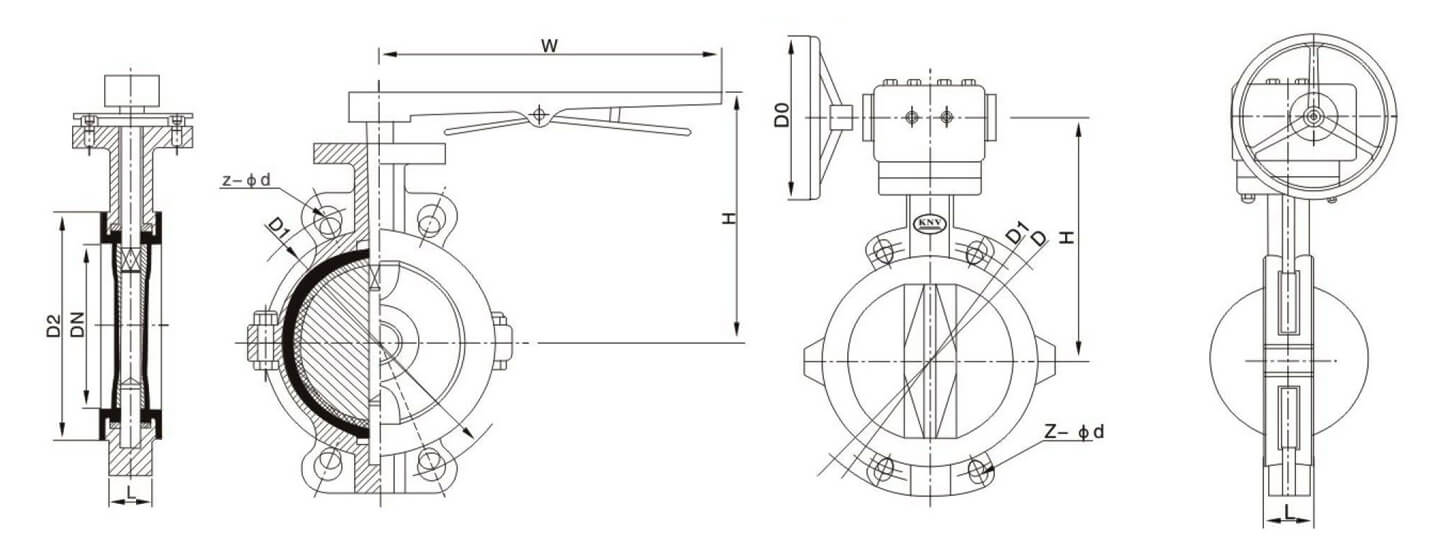

Wafer lined fluorine butterfly valve

Size:DN40~DN1200

Pressure Rating:1.0MPa/1.6MPa

Material:Cast iron/Ductile iron/Cast steel/Stainless steel

Design Standard: GB/12238

Inspection Standard: API 598

Application medium:liquids and gases (including steam)

Application Temperature:Normal Temperature (-40°C<T<120°C)

Applied projects: The products are widely used in the transportation of liquids and gases (including steam) in various types of industrial pipelines, especially the occasions with severe corrosive media, such as: sulfuric acid, hydrofluoric acid, phosphoric acid, chlorine, strong alkali, aqua regia, etc.

The butterfly valve uses a PTFE-lined butterfly plate with a spherical sealing surface, and a silicone rubber gasket at the base of the valve seat to adjust the sealing performance of the valve; the valve is easy to operate, tightly sealed, and has a long service life; It can be used to quickly cut off or adjust the flow. It is suitable for occasions requiring reliable sealing and good adjustment characteristics.

The valve body adopts a split type, and the sealing at both ends of the valve shaft is controlled by adding fluorine rubber to the rotating base surface between the butterfly plate and the valve seat; so as to achieve compact structure, beautiful appearance, reasonable process and reliable performance.

Ensure that the valve shaft is not in contact with the fluid medium in the cavity. It is very convenient to replace the valve shaft. The valve can be completed without removing the pipeline.

The products are widely used in the transportation of liquids and gases (including steam) in various types of industrial pipelines, especially the occasions with severe corrosive media, such as: sulfuric acid, hydrofluoric acid, phosphoric acid, chlorine, strong alkali, aqua regia, etc.

Features:

(1)The butterfly valve uses a PTFE-lined butterfly plate with a spherical sealing surface, and a silicone rubber gasket at the base of the valve seat to adjust the sealing performance of the valve; the valve is easy to operate, tightly sealed, and has a long service life;

(2)It can be used to quickly cut off or adjust the flow. It is suitable for occasions requiring reliable sealing and good adjustment characteristics.

(3)The valve body adopts a split type, and the sealing at both ends of the valve shaft is controlled by adding fluorine rubber to the rotating base surface between the butterfly plate and the valve seat; so as to achieve compact structure, beautiful appearance, reasonable process and reliable performance.

(4)Ensure that the valve shaft is not in contact with the fluid medium in the cavity. It is very convenient to replace the valve shaft. The valve can be completed without removing the pipeline.

Advantages:

| Body | Cast iron/Ductile iron/Cast steel/Stainless steel |

| Disc | PTFE |

| Seat | PTFE |

| Shaft | SS316 |

| Board stamen | Ductile iron/Cast steel/Stainless steel |

| Gasket in garden | Brass/Stainless steel |

| Bush | Bronze/PTFE |

| Sealing ring | Fluorine rubber/PTFE |

| Shelves ring | Spring coil |

| Seat back | Phenolic resin/Aluminium alloy |

| Sealing pressure cover | Fluorine rubber/PTFE |

| Cover | PTFE |

| Thrust bearing | Rolling |

| The awl forelock | Stainless steel |

Application

The concentric design is commonly used in the power generation, brewing, water and food industries and suitable for both gaseous and liquid service. Typically applied in chemical/petrochemical process, food and beverage, and pulp and paper etc.