Case

Case

During long-term operation, butterfly valves may malfunction due to various factors, including environmental factors, operation, and materials, impacting the normal operation of the system. In this article, WEIZIDON, based on years of experience, will provide a detailed analysis of common butterfly valve malfunctions, their causes, and solutions, and provide preventive and maintenance recommendations.

Major causes of poor sealing during butterfly valve operation include aging and deformation of the sealing ring, hardening of the sealing ring, aging of the valve stem packing, inclusions between the valve plate and the sealing ring, and inaccurate assembly of certain components.

Difficulty opening and closing or sticking butterfly valves is another common problem. Common causes include insufficient lubrication of the valve stem, corrosion or scaling of the valve plate and seat due to long-term inactivity, foreign matter deposited in the valve cavity that can cause the valve plate to become stuck, and transmission failure.

Valve stem fracture is often caused by improper operation or material defects. Common causes include defects in the valve stem material, forced opening and closing of the valve when the valve disc is stuck by foreign objects, and fracture caused by prolonged use.

Valve body or disc fracture is often caused by overpressure, improper materials, or water hammer. When system pressure or temperature exceeds the valve rating, or when the material's pressure or corrosion resistance is insufficient, the valve is susceptible to structural damage. The transient surge pressure from water hammer can also damage the valve body.

Common actuator problems include malfunctions of the handle, turbine, electric, or pneumatic actuator during operation, resulting in malfunction.

To ensure stable operation of butterfly valves and reduce malfunctions, WEIZIDOM recommends the following maintenance: regular lubrication, especially of the valve stem and transmission mechanism; selecting the appropriate butterfly valve model based on the project and the engineer's recommendations; and avoiding forceful operation and prolonged periods of inactivity for butterfly valves in long-term use. In addition, you can create an equipment operation log to regularly record opening and closing times, maintenance time, and component replacement for tracking and analysis.

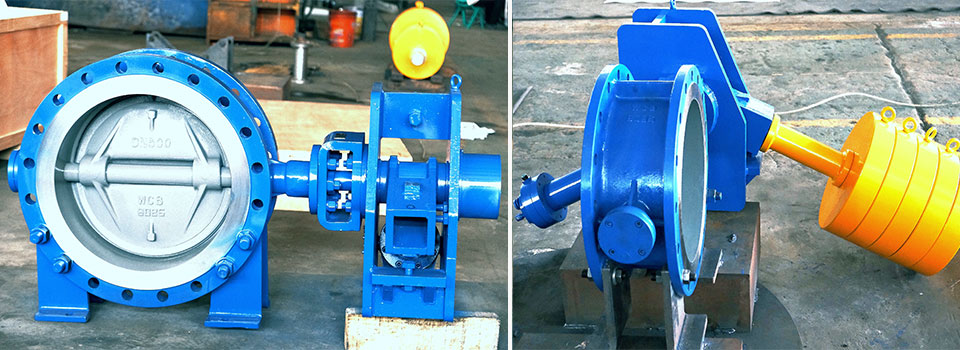

High-quality products are the fundamental guarantee for reducing butterfly valve failures. WEIZIDOM has specialized in the research, development, manufacturing, and export of industrial valves for over 20 years. With its own factory, we offer a wide range of butterfly valves, including wafer-type butterfly valves, lug butterfly valves, flange butterfly valves, and fire protection butterfly valves. These valves utilize high-strength valve bodies, wear-resistant and corrosion-resistant sealing materials, and high-precision machining processes. This ensures excellent opening and closing stability and sealing performance, enabling reliable operation under high-pressure, high-temperature, and corrosive conditions.

Why choose WEIZIDOM butterfly valves? WEIZIDOM butterfly valves come with an 18-month warranty, a professional after-sales service team, and overseas offices to provide timely after-sales service. If you are about to start, or are planning to purchase, butterfly valves in the near future, please contact us for a detailed product quote.

As a leading butterfly valve manufacturer in China, WEIZIDOM has over 20 years of experience in valve research and development, manufacturing, and export. To help customers better understand butterfly valves and their use, we have compiled the following frequently asked questions and answers.

A: Main causes include aging and deformation of the sealing ring, impurities trapped between the valve disc or sealing ring, worn valve seats, or improper assembly. Regular inspection of the seals and keeping the valve cavity clean are recommended.

A: WEIZIDOM butterfly valves utilize a high-strength valve body, wear-resistant sealing materials, and high-precision machining to ensure flexible opening and closing and reliable sealing. We offer an 18-month warranty and global after-sales support.

A: Yes, but prolonged use in throttling conditions is not recommended. Frequent use in a half-open position may cause wear on the valve disc and sealing ring.

A: Check the actuator for proper power and air supply, check the valve stem for rust or lack of lubrication, and check for foreign matter in the valve cavity. Disassemble, clean, or replace components if necessary.