Case

Case

Due to their advantages of rapid opening and closing, reliable sealing, and low flow resistance, ball valves have become core control components in pipeline systems in numerous industries, including petroleum, chemical, power, metallurgy, and irrigation. Based on years of production and export experience, WEIZIDOM recommends considering the following key parameters and application scenarios when selecting the right ball valve model:

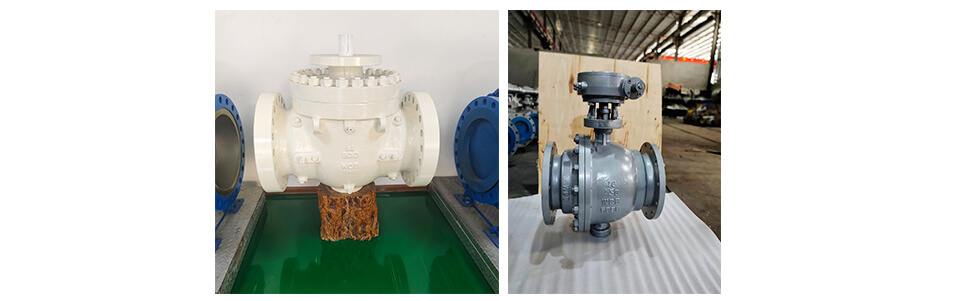

Floating Ball Valve: Its simple structure and low cost make it suitable for small-diameter (generally ≤ DN200) and medium-to-low-pressure (≤ Class 600) applications, such as on/off control of ordinary water and gas systems.

Fixed Ball Valve: The ball is fixed by upper and lower bearings, with the bearings absorbing the thrust of the media, resulting in low operating torque. It is suitable for large-diameter (up to DN1200), high-pressure (up to 42 MPa), and critical pipelines requiring higher reliability, such as the main valve for long-distance pipelines. V-shaped ball valve: The ball features a V-shaped cutout, enabling precise flow regulation (approximately equal percentage flow characteristics). It is suitable for processes requiring proportional regulation, such as chemical reactor feed control.

Fully welded ball valve: The valve body is fully welded, eliminating external leaks. It is stable and reliable for underground installation and is the preferred choice for buried oil and gas pipeline trunk lines.

Fire-resistant/fireproof ball valve: Utilizing metal-to-metal seals or specially designed soft seals, it can still provide an emergency seal even after the soft seal burns out. It is essential for use in systems with flammable and explosive media, such as those in the petroleum, chemical, and metallurgical industries.

Nominal Size (DN/NPS): Must match the pipe ID. Products are available for sizes ranging from small diameters (DN8/DN10) to very large diameters (DN1200). Nominal Pressure/Pressure Class (PN/Class): Must exceed the system's maximum operating pressure. A wide range of options is available, from vacuum to ultra-high pressure (up to 42 MPa/Class 2500).

Operating Temperature Range: The ball valve material and seal determine its temperature resistance. Standard ball valves are suitable for temperatures from -20°C to 200°C; cryogenic ball valves handle cryogenic media (such as liquid hydrogen, down to -254°C); and high-temperature ball valves (metal-hard seals) are suitable for temperatures above 200°C and even up to 815°C, such as steam and hot oil.

Carbon Steel/Stainless Steel (WCB, CF8, CF8M, etc.): Highly versatile, suitable for water, steam, oil, and generally corrosive media. 304 (CF8) and 316 (CF8M) stainless steels offer superior corrosion resistance.

Brass: Primarily used for water, oil, non-corrosive gases, and HVAC systems (DN15-DN50 is common). Pay attention to the pressure rating (PN10-PN64), operating temperature (-20°C to 200°C), and corrosion-resistant treatment (such as DZR anti-desincision treatment).

Seal Material:

Soft seals (PTFE, reinforced PTFE, rubber): Excellent sealing performance at room temperature, suitable for clean media ≤200°C. Low fluid resistance.

Metal seals: Resistant to high temperatures, high pressures, abrasive media, and particulate matter, they are often used in temperatures >200°C or harsh conditions. However, their sealing accuracy and shut-off leakage rate are generally slightly inferior to soft seals.

Manual: Handle or worm gear, suitable for small diameters, low-frequency operation, or maintenance applications.

Pneumatic/Electric/Hydraulic: Enables remote control, automation, or rapid opening and closing. Essential for large diameter, high-pressure valves, or applications requiring frequent adjustments.

Flange: Most commonly used, with various standards (e.g., ANSI, DIN, JIS, GB).

Threaded: Primarily used for small diameters (≤DN50), such as the common internal and external threads on brass ball valves.

Welded: Socket welding (for small diameters) or butt welding eliminates leakage risk and is suitable for high-pressure, high-risk media, or buried pipelines.

Oxygen Pipelines: Valves that have undergone rigorous degreasing must be selected to eliminate the risk of grease explosions.

Particle/Slurry Media: Ball valves with wear-resistant designs (e.g., orbital ball valves with special hard seals) are preferred.

Food/Pharmaceutical: Must meet sanitary standards (e.g., SMS, DIN, 3A). Material is typically 316L with a high-quality surface finish.

Irrigation Systems: Branch inlets are commonly used for their simple structure, low flow resistance, and ease of operation. However, they should be used with caution on main pipes to prevent water hammer.

Q1: Which ball valve should I choose for household water pipes or radiator valves?

A1: DN15-DN25 brass ball valves are a common choice. They have threaded connections, a nominal pressure of PN16 is sufficient, and they have a PTFE soft seal. They are suitable for water or heating water with a temperature range of -10°C to 120°C.

Q2: Which ball valve should I choose when adjusting water or air flow?

A2: A V-shaped regulating ball valve should be selected. Its V-shaped cutout provides a near-equal percentage flow characteristic, making it more suitable for precise flow control than a standard O-type ball valve.

Q3: Which ball valve should I choose for ultra-low-temperature media such as liquefied natural gas (LNG)?

A3: A dedicated cryogenic ball valve must be selected. They utilize low-temperature materials (such as L304 and L316), feature special structural designs (such as extended bonnets), and undergo cryogenic treatment to ensure reliable sealing and operation at temperatures as low as -196°C or even -254°C.

Q4: Can ordinary ball valves be used in high-temperature steam pipelines (>300°C)?

A4: No. Metal-sealed high-temperature ball valves must be used. Their seats and balls are made of special high-temperature alloys, and their design incorporates thermal expansion compensation to ensure sealing and long service life under high temperatures and high pressures.

Q5: What are the special requirements for main valves in buried oil/gas pipelines?

A5: Full-bore, fully welded ball valves are the preferred choice for buried mainline valves. The full bore ensures pig passage, and the fully welded valve body eliminates external leaks, requires no maintenance, and has a long buried service life and can withstand pipeline stress.

Q6: Why is the use of fire-resistant ball valves so important in flammable and explosive areas of chemical plants?

A6: Even if the soft seal of a fire-resistant ball valve is destroyed, its metal sealing pair (ball and metal seat) can still maintain a certain degree of sealing (in compliance with API 607/6FA standards), preventing large-scale leakage of the medium and causing secondary damage. This is a key guarantee of intrinsic safety.