Case

Case

Valves play a vital role in industrial piping systems. As the two most common valve types, gate valves and globe valves are often confused. Although they may appear similar, their structures, operating principles, and applicable scenarios differ significantly. Correctly distinguishing between these two valves is crucial to ensuring safe and efficient system operation. Drawing on years of experience in manufacturing and exporting, WEIZIDOM will provide an in-depth analysis of the differences between gate valves and globe valves from multiple perspectives to help you fully understand their characteristics.

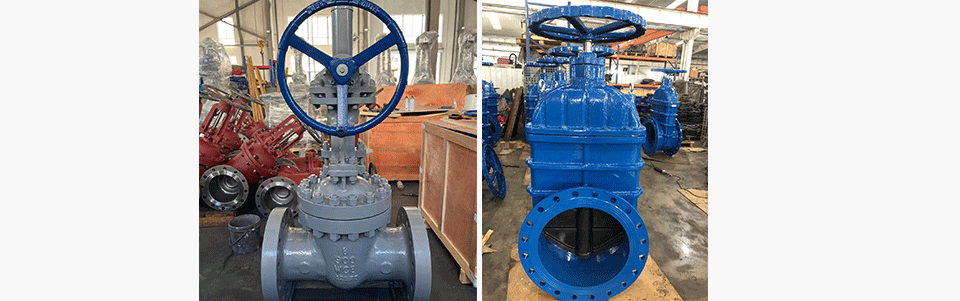

The core structure of a gate valve lies in its opening and closing component—the gate. The gate is typically wedge-shaped or parallel, and opens and closes the valve by vertically raising and lowering the valve stem. When the gate is fully raised, the flow path is unobstructed, with minimal resistance and virtually no change in flow direction. When the gate is fully lowered, the close contact of the sealing surfaces blocks the flow. This structure makes gate valves suitable for fully open or fully closed conditions, but not for flow regulation.

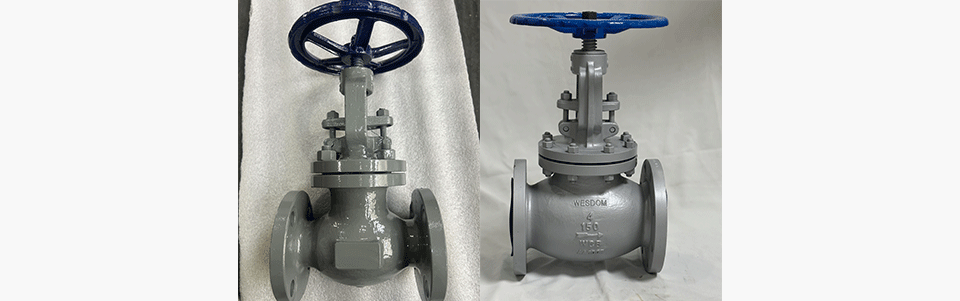

Globe valves use a disc as the opening and closing element. The disc moves along the centerline of the valve seat, controlling flow by changing the gap between the disc and the seat. The flow path of a globe valve is S-shaped, causing the fluid to change direction and resulting in greater resistance. Its structural design allows it to not only shut off the flow but also precisely regulate the flow rate, but at the expense of a higher pressure drop.

Flow Resistance: When fully open, a gate valve has a straight flow path, resulting in minimal flow resistance and low pressure drop. Globe valves, on the other hand, have a tortuous flow path, resulting in greater resistance and a significant pressure drop.

Sealing Performance: The sealing surface of a gate valve is susceptible to erosion and wear during opening and closing, and its sealing performance may deteriorate after long-term use. Globe valves, however, have relatively less wear on their sealing surfaces, resulting in more reliable sealing performance, making them particularly suitable for high-pressure applications.

Opening and Closing Speed and Operating Force: Gate valves have a long opening and closing stroke, resulting in slower operation but lower operating force. Globe valves have a short opening and closing stroke, resulting in faster operation, but typically require greater operating force due to the need to overcome fluid pressure. Flow Direction Requirements: Gate valves generally have no specific flow direction requirements and can be used in both directions. However, globe valves must strictly adhere to the flow direction indicated on the valve body (usually low inlet, high outlet). Failure to do so may result in difficulty opening and closing or seal failure.

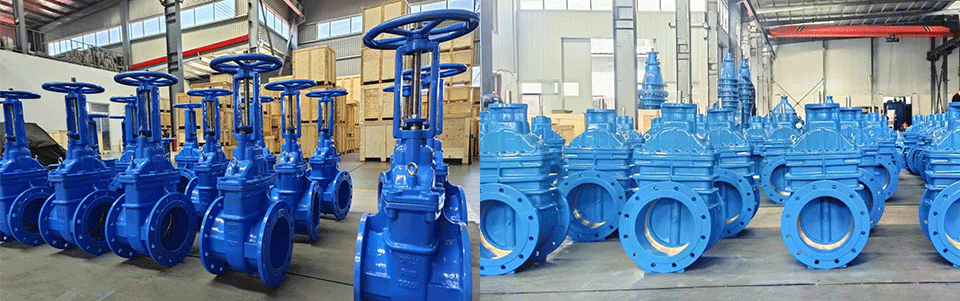

Due to their low flow resistance and full-bore port characteristics, gate valves are particularly suitable for large-diameter pipelines requiring low resistance, such as water supply mains and oil pipelines. They are particularly well-suited for applications requiring extended periods of full opening or closing. However, they are not suitable for flow regulation or for media containing suspended particles, as this may damage the sealing surfaces.

Globe valves are more suitable for applications requiring flow regulation or frequent operation, such as steam systems and regulating circuits in chemical production. Their excellent sealing properties also make them excellent for high-pressure, high-temperature media, such as critical shutoff points in power plants and petrochemical plants.

When selecting a valve, consider the media characteristics, pressure and temperature, operating frequency, and functional requirements. Choose a gate valve if low resistance and rapid shutoff are required; choose a globe valve if regulation or high-pressure sealing is required.

Look at their appearance: short and stout are gate valves, tall and thin are globe valves.

Feel the flow path: (Imagine) a straight flow path is a gate valve, while a curved flow path is a globe valve.

Turn the handwheel: (If it has a rising stem structure) a gate valve has a stem that rises when turned, while a globe valve has a stem that does not rise but only rotates.

Find the arrows: A straight arrow on the valve body indicates a gate valve, while an arrow marked "low in, high out" indicates a globe valve.