Case

Home / Case / User Manual / Installation and maintenance of electromagnetic flowmeter

Case

Installation and maintenance of electromagnetic flowmeter

Electromagnetic flow score for plug-in electromagnetic Flowmeter and pipeline electromagnetic Flowmeter.

Pipe electromagnetic Flowmeter and plug-in electromagnetic Flowmeter have the same installation requirements and different places. Total requirements for external environment and installation requirements.

①Electromagnetic flow meters should avoid installation in places where the temperature changes greatly or the equipment is exposed to high temperature radiation, if necessary, there must be heat insulation, ventilation measures

②Electromagnetic Flowmeter is best installed indoors, if must be installed outdoors, should avoid Rain Water pouring, water flooding and sun exposure, must have moisture-proof and sunscreen measures.

③Electromagnetic flow meters should avoid installation in corrosive gas environment, must be installed, ventilation measures;

④For the convenience of installation, maintenance and maintenance, there should be plenty of installation space around the flow meter;

⑤The installation place of electromagnetic Flowmeter should avoid magnetic field and strong vibration source, such as pipe vibration, there should be fixed pipe support on both sides of Flowmeter.

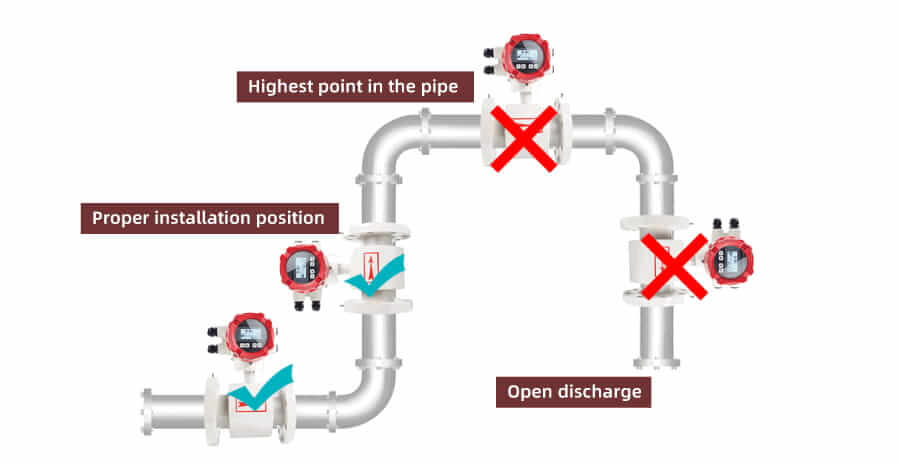

①It should be installed at the lower and vertical upper of the horizontal pipe to avoid installation at the highest and vertical lower of the pipe.

②Should be installed on the pipe rise.

③Installation in the open discharge pipe shall be installed at the lower part of the pipe.

④If the pipe drop exceeds 5 m, install the exhaust valve downstream of the sensor.

⑤The sensor must not be installed at the inlet and outlet of the pump and should be installed at the outlet of the pump.

⑥Installation requirements for plug-in electromagnetic flow meters

⑦Requirements for straight sections

⑧Main section of entrance / exit: entrance should ≥10×DN; exit should ≥5×DN;DN

⑨Docking location requirements

⑩In order to make the instrument work reliably and improve the measurement accuracy, the sensor should be well grounded without the interference of the external parasitic potential, and the grounding resistance should be less than 10.(if the metal pipe is well grounded, there is no need for a special earthing

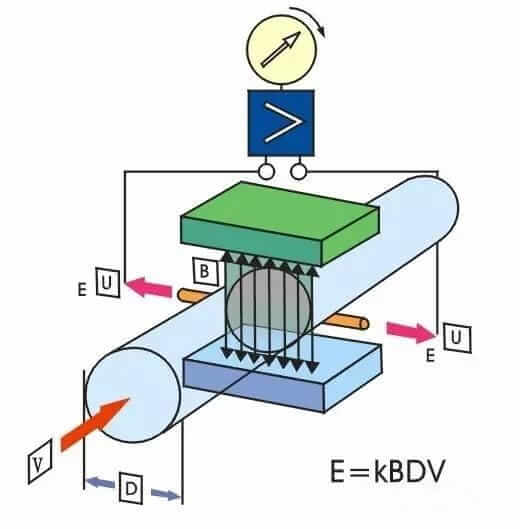

The measurement principle of pipeline electromagnetic Flowmeter does not depend on the characteristics of flow rate. If there is a certain turbulence in the pipeline and the vortex is produced in the non-measured area (such as elbow, tangential current limiting or semi-open stop valve upstream), it is independent of the measurement. If there is a steady eddy current in the measuring area, it will affect the stability and accuracy of the measurement.

At this time, some measures should be taken to stabilize the flow velocity distribution, increase the length of the straight pipe section before and after, adopt a flow stability, and reduce the cross section of the measuring point.

The insertion of electromagnetic Flowmeter is different according to the situation of field pipeline. For the situation that requires constant flow loading and unloading or does not allow medium overflow, ball valve should be installed, that is, insert electromagnetic Flowmeter with ball valve structure should be selected. Prepare to weld the connecting pipe to the opening of the pipe.

The plug-in electromagnetic Flowmeter has the advantages of absolute installation and price, and the flow detection is only related to the insertion depth, so the Flowmeter has wide versatility and strong interchangeability. One model can be used for fluid measurement requirements of various specifications.