Case

Case

In water treatment systems, valves are key switches controlling water flow. Gate valves and globe valves are the most common, but their functions differ significantly. Choosing the right valve ensures a stable and efficient system. So, when should you choose a gate valve and when should you choose a globe valve?

To make the right choice, you first need to have a deep understanding of the inherent nature of each.

What is a gate valve?

The core component of a gate valve is a disc positioned perpendicular to the flow direction. Its operating principle is as its name suggests—like a gate. Rotating a handwheel or actuator causes the disc to move vertically within the valve body. When the disc is fully raised, the flow path is completely open, with a diameter roughly the same as the pipeline, allowing fluid to flow in a straight line almost unimpeded with minimal resistance loss. When the disc is fully lowered, the fluid path is blocked.

This structure determines the gate valve's core function: fully open or fully closed, that is, blocking or connecting the medium. It is not suitable for flow regulation. When the gate disc is half-open, the high-speed flow of media can cause erosion and vibration on the lower half of the disc, easily damaging the sealing surface, leading to valve leakage and poor adjustment accuracy.

What is a globe valve?

The structure of a globe valve is quite different. Its valve core (a plug- or needle-shaped component) moves along the centerline of the valve seat, changing the annular opening between the disc and the seat, thereby regulating flow. Crucially, the globe valve's flow path is S-shaped, forcing the fluid to change direction within the valve, resulting in significantly greater flow resistance than a gate valve.

This inherently high flow resistance may seem like a disadvantage, but it becomes an advantage in applications requiring flow regulation. It reduces the impact force on the disc during flow regulation, enabling precise and smooth flow control, and the wear on the sealing surface is far less than with a half-open gate valve.

Understanding their fundamental principles allows us to precisely match them to the needs of different water treatment processes.

Preferred Applications for Gate Valves:

Applications requiring full opening and closing: This is the primary application for gate valves. For example, in municipal water mains, factory water inlets, and the inlets and outlets of large pools, where a section of pipeline needs to be completely isolated for maintenance. The extremely low flow resistance of a fully open gate valve means minimal energy loss, effectively saving energy for long-term pumping stations.

Applications where the media is clean and requires no adjustment: Media such as raw water, clean water, and reclaimed water in water treatment are relatively clean and less prone to impurity accumulation, making gate valves suitable for use. However, if the media contains a large amount of particulate matter (such as untreated sewage), these impurities can easily accumulate in the gate disc groove, causing the gate disc to become stuck and unable to open and close properly.

Preferred Applications for Globe Valves:

Applications requiring precise flow or pressure regulation: This is where globe valves offer irreplaceable advantages. For example, chemical dosing lines require precise control of dosage; the inlet pressure of reverse osmosis (RO) systems requires regulation; and the backwash intensity of filtration systems requires control of backwash intensity. In these situations, globe valves are the better choice.

Where frequent opening, closing, or adjustment is required: Because the sealing surfaces of their disc and seat are designed to be more resistant to erosion and require relatively low operating torque, globe valves are more suitable for frequent operation. Frequently leaving gate valves in a partially open position can accelerate their wear.

Where space is limited: Globe valves are generally more compact than gate valves of the same diameter (especially Y-type globe valves), requiring less height for installation.

Where bidirectional sealing is required: Most gate valves are unidirectional (usually with an arrow on the valve body indicating the direction of flow). Installing them in the wrong direction can compromise sealing effectiveness. Globe valves, on the other hand, typically provide bidirectional sealing and are less critical to their orientation

| Characteristics | Gate Valve | Gate Valve Globe Valve |

| Flow Resistance | Minimal (fully open) | Relatively large |

| Main Function | Shutoff/Connection | Regulating/Shutoff |

| Sealing Performance | Good (fully closed) | Excellent |

| Opening/Closing Speed | Slow (long stroke) | Fast (short stroke) |

| Installation Space | High Height Requirement | Low Height Requirement |

| Regulating Performance | Poor, strictly prohibited for regulation | Excellent |

| Media Flow Direction | High unidirectionality requirement | Bidirectional sealing is common |

In summary, the choice between gate valves and globe valves is essentially a decision between "on/off" and "regulating" functions. The key to optimizing the design of a water treatment system lies in precisely matching them to process requirements: gate valves ensure low-consumption and unobstructed flow in the main line, while globe valves provide precise and reliable regulation of the branch line.

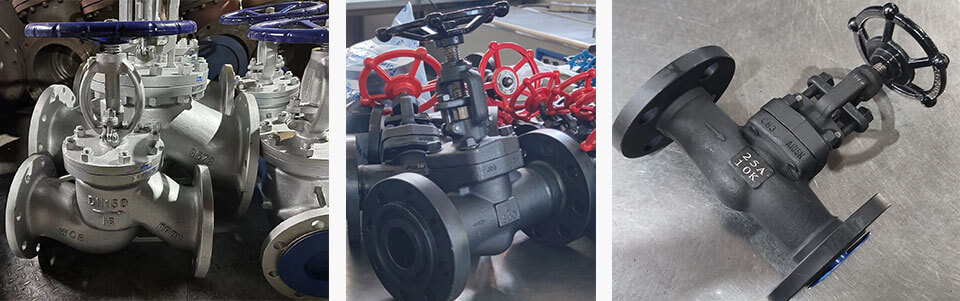

As a professional valve manufacturer and supplier, WEIZIDOM can provide a variety of gate valves and globe valves to meet your needs. Please contact us for detailed product information.