Case

Case

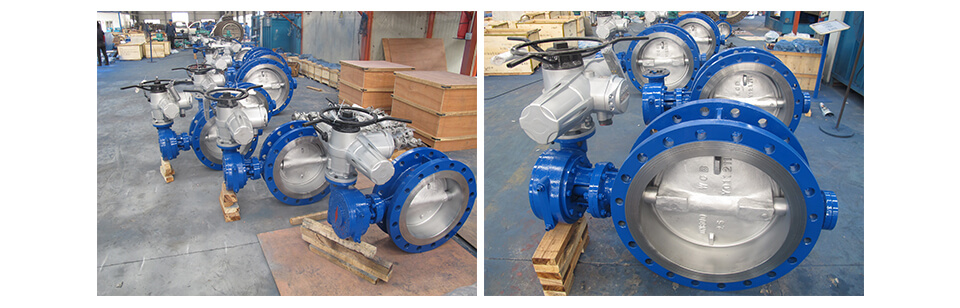

Butterfly valves, with their simple structure and flexible operation, play a key role in various fields, including industry, municipal administration, and energy. Depending on whether they rely on external power sources for automated control, they can be divided into manual and electric butterfly valves.

Manual butterfly valves: Purely mechanical, they rely on manual rotation of a handle or handwheel to actuate the valve stem. While simple in structure, operating force increases with pipe diameter. They are suitable for small-diameter pipes and low-frequency operation (such as household water supply and small irrigation systems).

Electric butterfly valves: Driven by an electric actuator, they support remote control and automated adjustment. They offer faster opening and closing speeds and constant torque, making them suitable for large-diameter pipes (DN200 and above) or high-frequency operation environments (such as municipal water supply and chemical production lines).

Typical Applications of Manual Butterfly Valves

Low-cost, low-frequency operation scenarios: Small irrigation systems, laboratory water supply pipelines, and other applications requiring infrequent adjustments; water valve control for household and small appliances, such as water heater inlet valves.

Special media handling: Pipeline shutoffs for media containing particles or high viscosity (e.g., slurry, sewage); Corrosive gas pipelines such as sulfuric acid and coal gas (requiring corrosion-resistant sealing materials).

Space-constrained environments: Installation requires a compact space that facilitates manual operation; Wafer connections for short pipes between two flanges (e.g., chemical reactor bypasses).

Typical applications of electric butterfly valves Application Scenarios

Automated Industrial Systems: Remote flow control of municipal water supply mains and central air conditioning water circulation systems; safe shutoff of high-risk media (such as toxic gases) in chemical production lines.

Harsh Environments: High-temperature and high-pressure operating conditions (such as power plant cooling systems, with a temperature resistance of up to 425°C); high altitude or confined spaces.

Precision Control Requirements: Aseptic fluid regulation in the pharmaceutical industry; dynamic pressure balancing in natural gas pipelines.

Manual butterfly valves offer low maintenance costs, but seals (such as rubber valve seats) require regular replacement. While electric butterfly valves have a long lifespan, motor and control system failures can affect overall stability. Therefore, WEIZIDOM recommends that manual butterfly valves be prioritized for initial investment, as they cost only 1/5 to 1/10 of electric valves. Electric valves also save on ongoing manual inspection costs, requiring regular checks of the circuit and seals, while manual valves only require replacement of consumable parts such as the valve seat.

Manual valves are preferred for small projects with limited budgets, simple operation, and no need for remote control. For automated production lines, hazardous media, or industrial systems requiring high-frequency regulation, electric valves are a must.

Q: What is the core difference between manual and electric butterfly valves?

A: Operation: Manual butterfly valves rely on manual rotation of a handwheel/handle, while electric butterfly valves are driven by a motor and support remote or automated control.

Q: Are manual butterfly valves suitable for large-diameter pipes?

A: Suitable, but with limitations: Pipes below DN200 can be operated directly; pipes above DN200 require a turbine reducer to reduce torque. Frequent and prolonged operation may cause valve stem wear, requiring regular lubrication.

Q: How do the two valves compare in sealing performance?

A: Electric butterfly valve: The soft seal design offers lower leakage, and the grooved seat prevents deformation. Manual butterfly valve: The metal seal is suitable for high temperatures and high pressures, but the seal ring may need replacement after prolonged use.

Q: How do I troubleshoot an electric butterfly valve? A: Common fault types and troubleshooting methods:

Power supply failure:

Use a multimeter to check for stable voltage.

Check wiring for aging and loose connectors.

Limit switch abnormality:

Observe the valve for any stuck movements. Manually rotate the valve plate to test for resistance changes.

Check whether the feedback signal is consistent with the actual position.