Case

Case

As a clean energy source, natural gas is increasingly used in industrial production, city gas, and power generation. Flowmeters, key equipment for natural gas metering and trade settlement, have a direct impact on measurement reliability, operational economics, and safety. Therefore, scientific and rational selection of natural gas flowmeters is crucial.

The selection of a natural gas flowmeter requires comprehensive consideration of multiple factors, including fluid characteristics, operating conditions, metering requirements, and economic efficiency. First, parameters such as natural gas pressure, temperature, flow range, density, and composition must be clearly defined, as these directly impact the flowmeter's suitability. Secondly, the installation environment, such as pipeline diameter, vibration conditions, and electromagnetic interference, must also be considered. Furthermore, measurement accuracy requirements, pressure loss, maintenance costs, and service life are also key considerations in the selection process.

Currently, the most common natural gas flowmeters on the market include turbine flowmeters, ultrasonic flowmeters, and vortex flowmeters.

Turbine flowmeters: They offer high accuracy (up to ±0.5-1%), a wide range, and fast response, making them suitable for medium- and high-pressure applications with low to medium flow rates. However, they require high media cleanliness, bearings are susceptible to wear, and require regular maintenance. They are also unsuitable for pulsating flows or natural gas containing liquids.

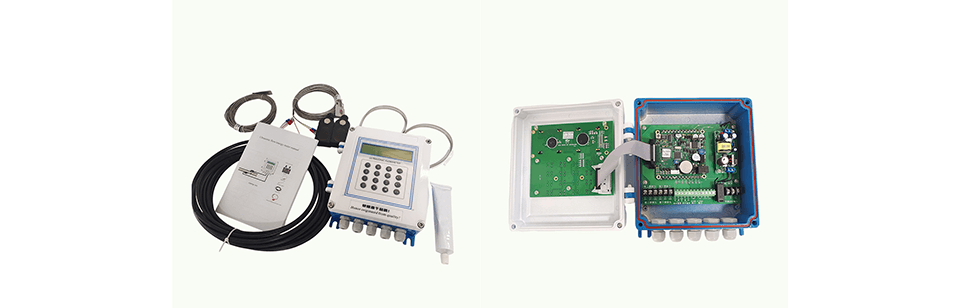

Ultrasonic flowmeters: They offer no pressure drop, high accuracy (up to ±0.5-1%), a wide range, and no moving parts, requiring minimal maintenance. They are particularly suitable for large-diameter pipelines and trade settlements. However, they are more expensive, require stringent installation requirements, and are significantly affected by flow field disturbances.

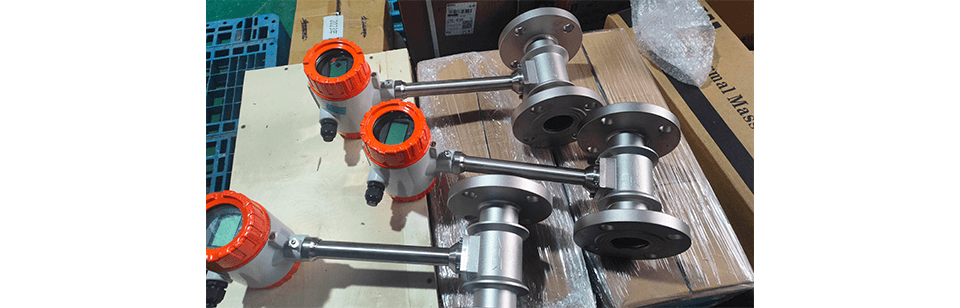

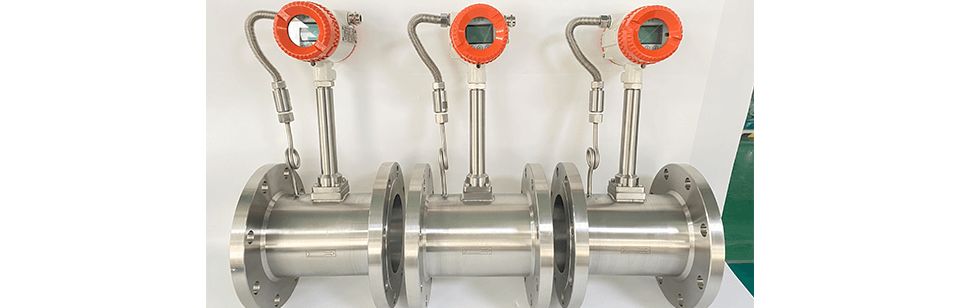

Vortex flowmeters: They have a simple structure with no moving parts, low pressure drop, a piezoelectric stress sensor, high temperature resistance (-40-350°C), and a 10:1 range ratio. They support pulse/4-20mA output and are explosion-proof up to ExdⅡCT4, but offer limited vibration resistance.

The actual selection process should be considered based on the specific application scenario. For example, in city gas transmission and distribution, turbine flowmeters are an option for small and medium flow rates; ultrasonic flowmeters are preferred for high-pressure, high-flow trade settlements. At the same time, the following points should also be considered:

Accuracy and Stability: Trade settlements require high accuracy and long-term stability, so ultrasonic or turbine flowmeters are preferred; process control can lower these requirements.

Installation and Maintenance: Where installation space is limited or maintenance is difficult, ultrasonic flowmeters with no moving parts can be considered.

Economical Considerations: While meeting technical requirements, a comprehensive evaluation should be made of initial investment, operating costs, and maintenance expenses.

How does a vortex flowmeter measure gas flow?

The Karman vortex effect generates alternating vortices as the fluid passes through the generator. The frequency of these vortices is proportional to the flow velocity. The sensor detects this frequency and converts it into a flow signal.

Why do turbine flowmeters need filters?

High-speed turbine blades are susceptible to particle wear. Filters trap impurities and protect mechanical components.

How do I determine if a flowmeter needs replacement?

If the error after calibration still exceeds ±1.5% (for trade settlement) or ±2.5% (for industrial monitoring), and the repair cost exceeds 30% of a new meter, replacement is recommended.

What precautions should be taken when measuring natural gas containing water?

A gas-liquid separator must be installed and drained regularly. Otherwise, liquid accumulation will cause a volume measurement error of up to ±5%.

How should I select a meter for high-pressure applications?

The nominal pressure must be ≥1.6 MPa. Metal spiral wound gaskets must be used in flange connections to prevent seal failure.