Case

Case

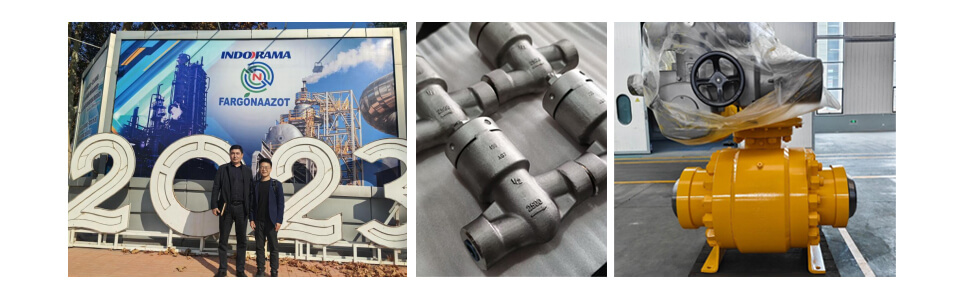

Discover how WEIZIDOM's PTFE-lined butterfly valves & forged steel valves ensure safety at Uzbekistan’s 2nd largest chemical factory. Trusted by Farg'onaazot for quality + price. Request your project review now!

When Farg'onaazot – Uzbekistan’s second-largest chemical complex – needed fail-safe fluid control for corrosive processes, they turned to WEIZIDOM's engineered valve solutions. Operating in one of Central Asia’s most demanding industrial environments, this partnership showcases why global leaders choose valves that balance precision, durability, and cost-efficiency.

* Highly corrosive media: Acids, alkalis, and volatile compounds

* Temperatures up to 300°C in reactor feed systems

* Zero tolerance for leakage under Uzbek safety regulations (UzGOST standards)

Traditional valves failed within months, causing costly shutdowns.

* Reinforced PTFE Seat: Withstands pH 0-14 exposure

* 316L Stainless Steel Disc: Electropolished to Ra 0.8μm

* Fire-Safe Design: API 607 certified

* Size Range: DN80 to DN1200 (3"-48")

“WEIZIDOM's lined valves cut our maintenance costs by 70%.” – Farg'onaazot Chief Engineer

| Parameter | Generic Valves | WESDOM Forged Valves |

| Pressure Rating | Class 600 | Class 1500 |

| Cycle Life | 10,000 cycles | 500,000 cycles (TESTED) |

| Leakage | ANSI IV | ANSI VI (Zero Leakage) |

| Temperature | -29~200°C | -196~550°C |

* Ammonia synthesis control units

* High-pressure steam isolation (42 bar)

* Emergency shutdown (ESD) systems

* 24-Step Quality Assurance: From raw material spectrometry to cryogenic testing

* Dual Certifications: ISO + CE

* Smart-Ready: IoT-enabled valves with pressure/temp monitoring (Farg'onaazot Phase 2 rollout)

Uzbekistan-Proven, Globally Trusted

*“We audited 7 valve suppliers. WESDOM delivered the only solution passing our 600-hour salt spray test.”* – Procurement Director, Farg'onaazot

* Zero unplanned downtime in 18 months of operation

* 30% faster valve actuation vs. previous suppliers

* Full compliance with Uzbek Chemical Safety Standards

Whether you operate in:

* Chemical/Petrochemical Plants

* Fertilizer Production

* Pharmaceutical Manufacturing

* Water Treatment

We deliver valves engineered for your exact media, pressure, and safety requirements.

Request Your Project Review

Get Custom Recommendations: Send your technical specs → eileen@wsdsolution.com