Product

Product

Aluminum Butterfly Valve

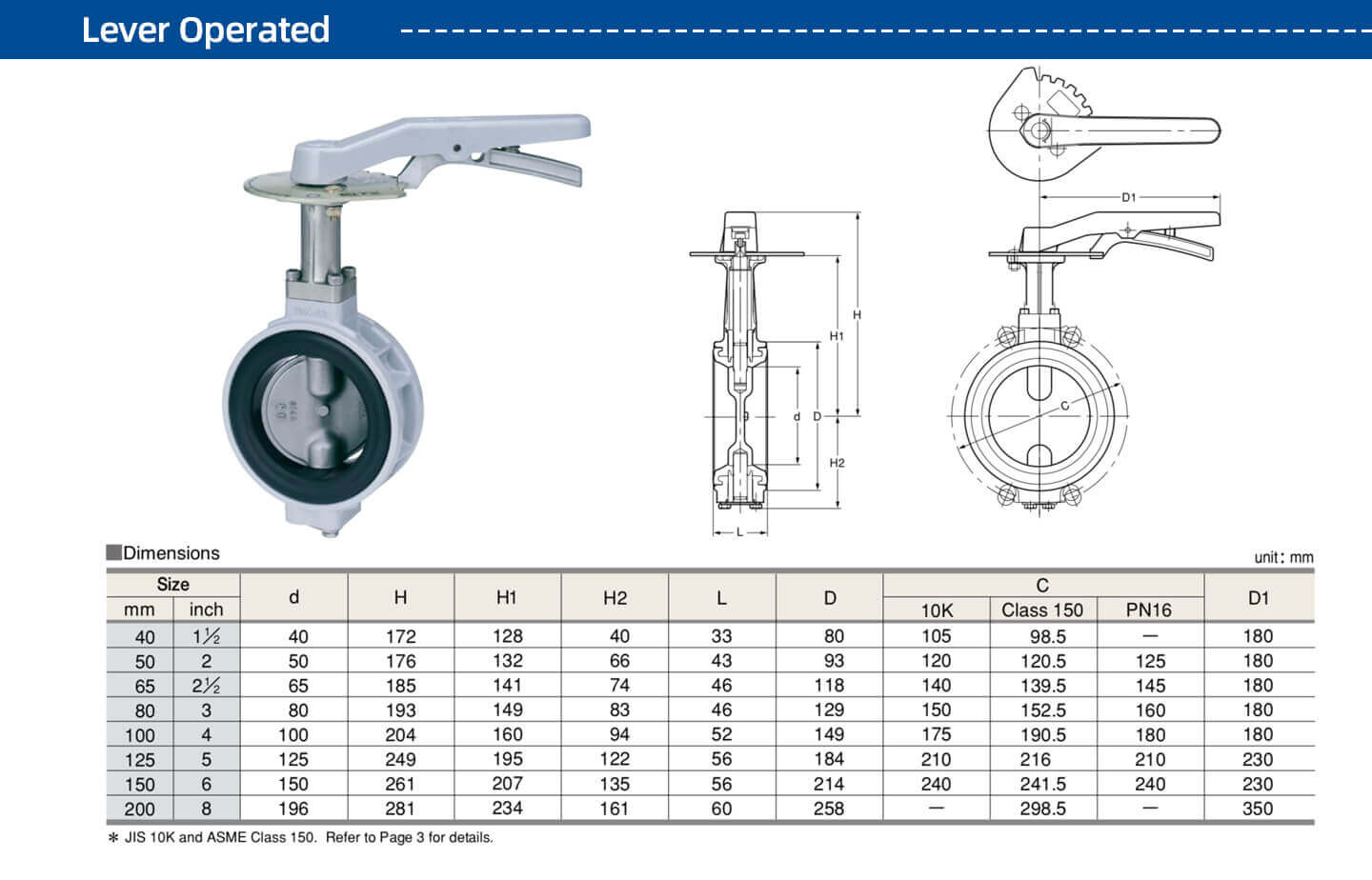

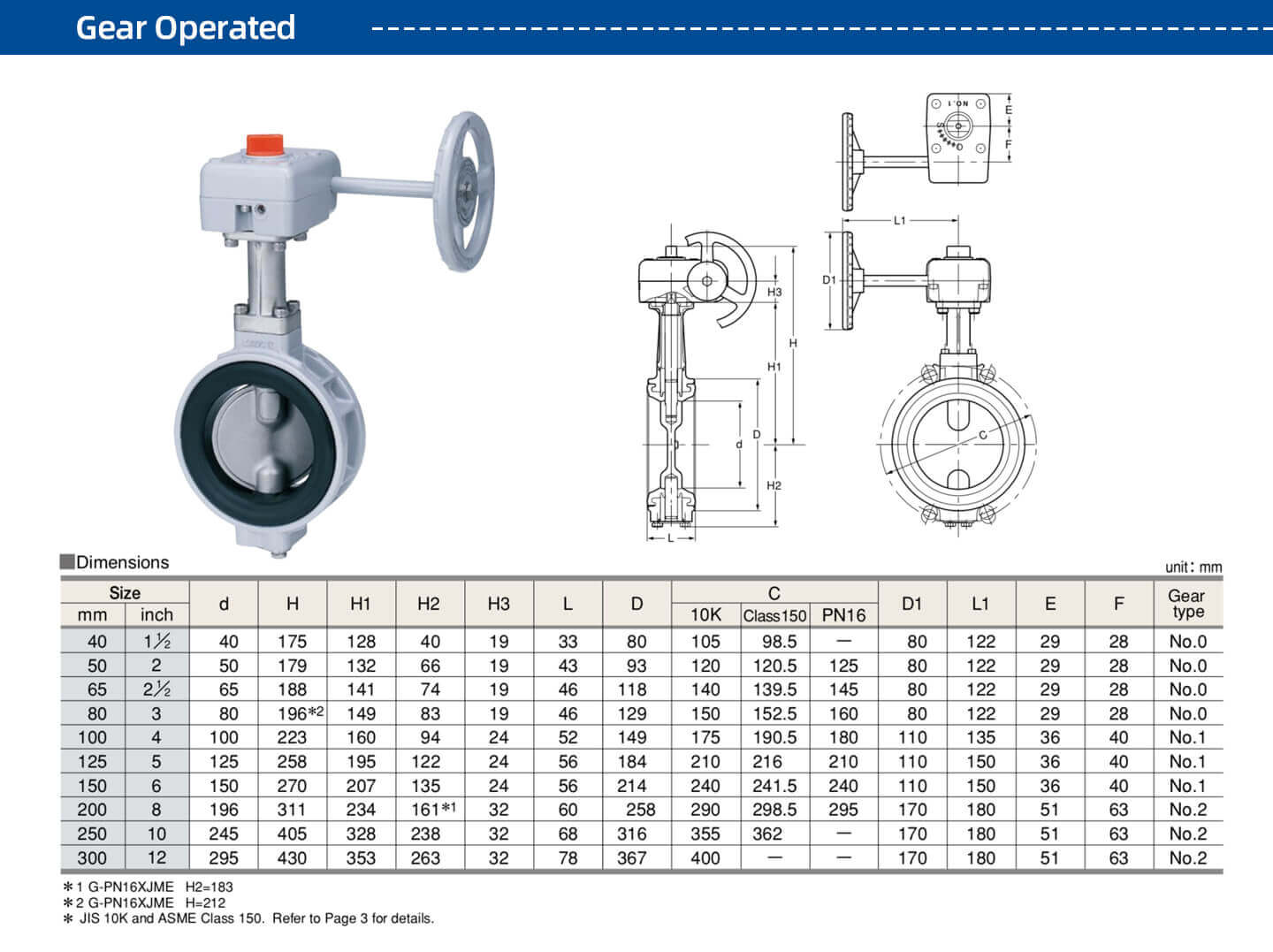

Size:1-1/2"-12"

Pressure Rating:PN10 & PN16 150LB

Material:ADC12

Design Standard: BS 5155,EN593, API 6

Inspection Standard: EN12266, API 598,GB/T 13927-9

Application medium:Water

Application Temperature: NBR 0-70G,EPDM 0-120'℃

Applied projects: air conditioning system

WESDOM could provide various butterfly valves which can be widely applied in all many kind of industrial fluids. The sizes from DN25~DN2400 are all available. The standard we can comply DIN, JIS, GB, API 609, etc. CHOOSE WESOM, CHOOSE QUALITY!

Features:

(1)Carefully designed EPDM seats have the following unique features that ensure their functional stability, high sealing performance, and long life:

Self-reinforced ribbing

Wide disc seating contact

Dual stem seal bearings;

(2)Wide disc seating contact for high sealing performance;

(3)Reinforced ribbing minimizes valve operating problems such as distortion, skidding, and exfoliation of rubber liners caused by line pressure load and friction with metal discs;

(4)Stem seal bearings are assembled on the top and bottom stems for stable sealing;

(5)Light aluminum alloy valve body, small torque, easy to use and install;

(6)Aluminum die-cast valve body to prevent corrosion;

(7)Some multi-level progressive contact valve seat design allows the valve plate to gradually contact the valve seat during the closing process, which reduces unnecessary torque while ensuring good sealing performance, thereby prolonging the service life of the valve seat;

(8)Some valve stem sealing rings prevent fluid leakage;

(9)Valve seats of different materials adapt to different working conditions and have good anti-corrosion and sealing performance;

(10)The trajectory of the spherical valve plate makes the valve rotate flexibly and freely.

(11)The valve plate is processed as a complete spherical shape. Each part of the sealing surface is a part of the spherical surface, even the axial sealing surface at the upper and lower parts of the valve plate.

This is no exception.

When the sealing surface is in contact, it is quite smooth despite the contact.

Therefore, the torque is reduced and the sealing performance is improved, especially the friction at the axial seal is reduced. The seat life of the technology has been tripled.

Advantage:

(1)The valve body is made of light aluminum alloy body, with low torque, preventing rust, and preventing long-term circulation of chilled water in the air conditioner.

(2)The low temperature of the fluid in the pipeline follows the conduction of the butterfly valve metal material and exchanges with the ambient air temperature to produce condensation.

(3)The unique multi-level progressive contact seat design of the anti-condensation butterfly valve makes the valve plate gradually contact the seat during the closing process.

Parameter:

| Material | |

| Parts | Aluminum Die-cast/Equivalent ASTM B85-84-383.0 |

| Neck | 304 Stainless Steel |

| Stem | (Equivalent ASTM A276 Type 410) |

| Disc | A351 Gr. CF8M |

| O-ring | EPDM |

| Rubber seat | EPDM |

| Bottom stem | (Equivalent ASTM A276 Type 410) |

Application

Products are widely used in industries such as fire-fighting pipelines, drainage, sewage, food, heating, gas, ships, hydropower, metallurgy, energy systems, and textiles.