Product

Product

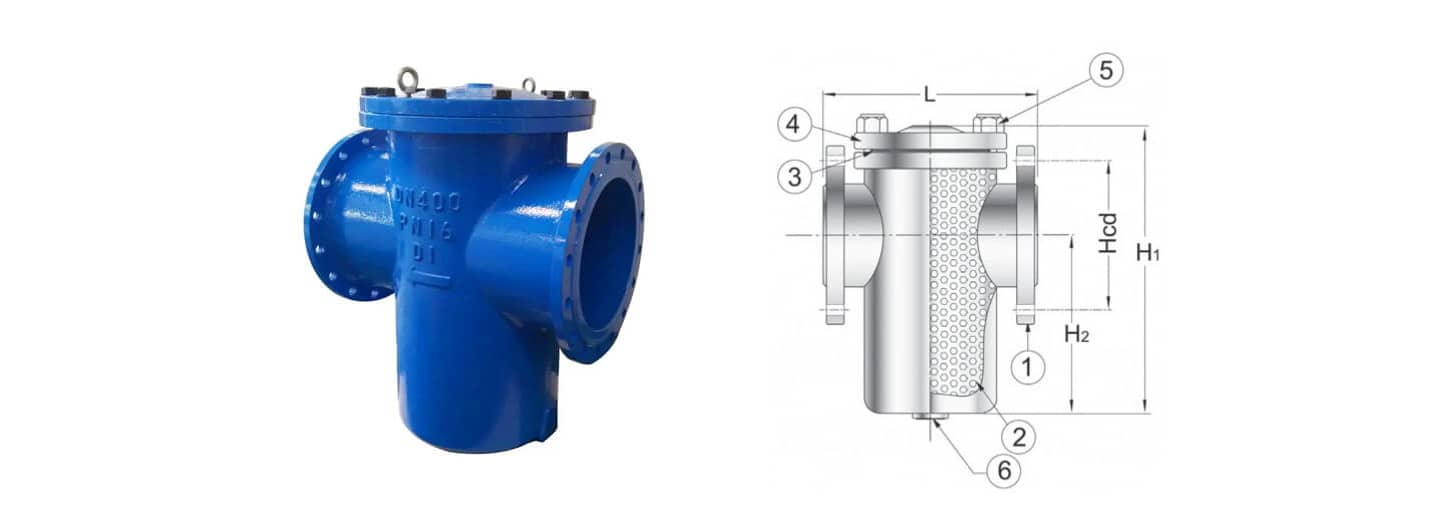

Basket Type Strainer

Size: 2”~24”

Pressure Rating:PN10-40, 150LB-300LB

Material:Carbon steel、 Stainless Steel

Design Standard:EN13709,ASME B16.34

Inspection Standard:EN12266,API598

Application medium:For Water, Oil ,Gas

Application Temperature:0-200℃

Applied projects:Petroleum、Electricity、Metallurgy、Water、Sewage、Energy、Construction

The Y-type strainer is an indispensable device for the pipeline series conveying the medium. It is usually installed at the inlet end of the pressure reducing valve, pressure relief valve, fixed water level valve or other equipment to eliminate impurities in the medium to protect the valve and the normal use of the device.

The Y-type strainer is an indispensable device for the pipeline series conveying the medium. It is usually installed at the inlet end of the pressure reducing valve, pressure relief valve, fixed water level valve or other equipment to eliminate impurities in the medium to protect the valve and the normal use of the device.

WESDOM filter has the characteristics of advanced structure, low resistance and convenient sewage discharge. The applicable medium can be water, oil and gas. WESDOM could provide Y type and basket type strainers.

Basket type strainer (Basket type filter), is mainly composed of over charge, filter blue, flange, flange cover and fasteners and other components. When the liquid enters into the filter through the director of blue, solid impurities are blocked in the filter blue, while the clean fluid through the filter basket, discharged from the filter outlet when cleaning.

When the head of the bottom of the drain plug, drain fluid, remove flange, cleaning and reinstall it. Therefore, maintenance is extremely easy to use. Features: strong sewage sewage, convenient circulation area, small pressure loss and simple structure;

The basket type or pot type strainer is characterised by a vertically orientated chamber, typically larger than that of a Y-type strainer. Size for size, the pressure drop across a basket strainer is less than that across the Y-type as it has a greater free straining area, which makes the basket type strainer the preferred type for liquid applications. As the dirt holding capacity is also greater than in Y-type strainers, the basket type strainer is also used on larger diameter steam pipelines.

Basket type strainers can only be installed in horizontal pipelines, and for larger, heavier basket strainers, the base of the strainer needs to be supported.

When basket type strainers are used on steam systems, a significant amount of condensate may be formed. Consequently, strainers designed for use in steam systems usually have a drain plug, which can be fitted with a steam trap to remove the condensate.

Basket type strainers are commonly found in a duplex arrangement. A second strainer is placed in parallel with the primary strainer, and flow can be diverted through either of the two strainers. This facilitates cleaning of the strainer unit whilst the fluid system is still operating, reducing the downtime for maintenance.

Design Feature:

(1)Full bore

(2)Bolted cover

(3)Compact design

(4)High filtration accuracy

(5)Faster filter speed

(6)Adjustable

(7)Online repair

Design Standard:

Design: ASME B16.34

Face to face: ASME B16.10

Flange end: ASME B16.5 / ASME B16.47

Test: API598

Technical Specification:

Size: 2”~24”

Class: 150Lb~600Lb

Connection: Double flange

Temperature: 0°C to +200°C

Application: water / pipeline system

Application

Strainers are widely used in the fields of metallurgy, chemical industry, petroleum, paper making, medicine, food, mining, electric power and urban water supply.

They are used in industrial wastewater, filtration of circulating water, regeneration of emulsions, filtration of waste oil, continuous casting water systems in the metallurgical industry, blast furnace water systems, and high pressure water descaling systems for hot rolling. It is an advanced, efficient and easy to operate fully automatic filtration device.