Product

Product

Double eccentric butterfly valve

Size:4”~72”

Pressure Rating:PN10,PN16,150LB

Material:Ductile Iron, WCB

Design Standard: GB12238,BS5155,EN593,API609

Inspection Standard: API598, EN12266, GB/T 13927

Application medium:water

Application Temperature:-10℃~120℃

Applied projects:Petroleum/Electricity/Metallurgy/Water/Sewage/Energy/Construction

WESDOM double eccentric butterfly valves with tilted disc are designed for easy operation and long service life. The disc seal is made of WESDOM’s drinking water approved EPDM rubber featuring an excellent compression set and ability to regain the original shape. The high quality epoxy coating and fully encapsulated shaft/disc connection ensure optimal corrosion protection and durability.

Double eccentricbutterfly valve Product description:

Flange butterfly valve, mounting between flanges PN10/PN16/A150, with gear box.

The range of WESDOM valves can be used for overground installation, in valve chambers and buried systems.butterfly valves in a range of DN 150 to 2000 mm and PN 10, 16 and 25 bar have been designed to isolate the flow of fluid in:

①potable water supply pipelines and treatment plants.

②transportation of filtered and recycled water.

③irrigation distribution networks.

④water-pumping stations and hydroelectric plants.

⑤reservoirs.

Features:

①Double eccentric design releases seal compression after only few degrees of opening resulting in low operating torque

②Disc firmly fixed to the shaft to prevent fluttering and a slight tilt allows for precise adjustment of the closed position

③Disc seal profile and rubber quality ensure low closing torque

④All rubber parts drinking water approved by multiple institutes

⑤Fasteners in stainless steel, A2

⑥Stainless steel shaft

Machined and epoxy coated ductile iron seat integrated in the body

⑦All threaded connections are sealed with O-rings for protection against medium and environment

Radial bearings in self-lubricating PTFE/bronze composite

⑧Shaft ends fully encapsulated in the disc and fixed with O-ring sealed dowels held in place with a security plate. Key and keyway as backup

⑨Replaceable shaft seals with two EPDM O-rings; gaskets to the exterior in hydrocarbon resistant NBR

⑩Coated with blue RAL 5017 FBE to DIN 3476, GSK and approved by WRAS-DVGW/W270/UBA, 250µm

Double eccentric butterfly valve Standard:

Design and Manufacture Conform to EN 593, API609, JIS

Flange dimensions Conform to EN 1092-2 PN10, PN16, JIS5K, JIS10K,ANSI B16.1,DIN2501,BS4504

Face to Face dimensions Conform to EN558 series

Top Flange dimensions Conform to ISO5211

Testing Conform to API598、EN12266-1

Standard:

Body Test: 1.5 times the working pressure with water. This test is performed after valve assembly and with disc in half position open, it is called as a body hydro test.

Seat Test: 1.1 times the working pressure with water.

Special Test: On request, any other test can be carried out according to special instruction by client.

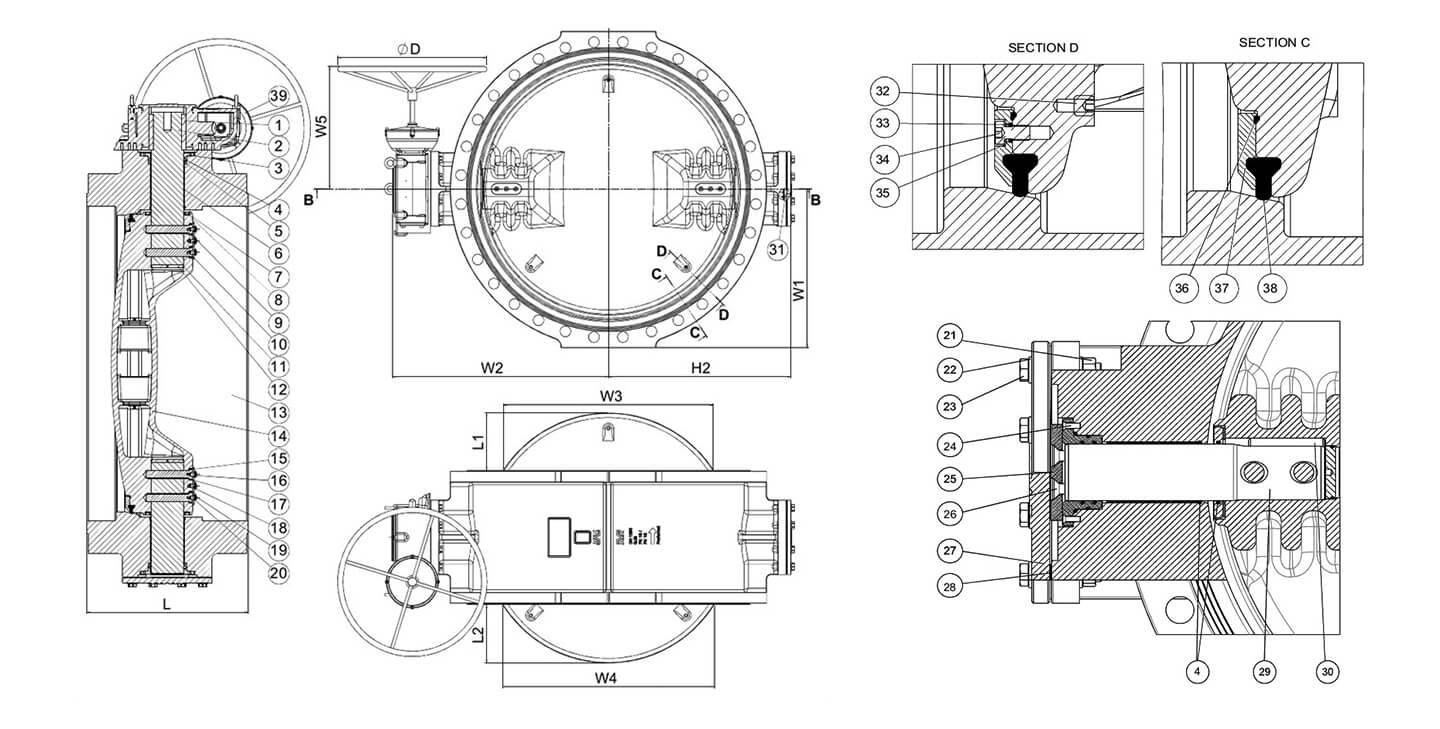

| 1 | 2 | 3 | 4 | 5 | 6 |

| Key | Valve shaft | Seal housing | O-ring | O-ring | Radial bearing |

| Stainless steel A2 | Stainless steel AISI 420 | Bronze | EPDM rubber | EPDM rubber | Bronze/PTFE composite |

| 7 | 8 | 9 | 10 | 11 | 12 |

| Disc cover | Disc cover gasket | O-ring | Dowel | O-ring | Plug |

| Stainless steel | EPDM rubber | EPDM rubber | Stainless steel A2 | EPDM rubber | Steel |

| 13 | 14 | 15 | 16 | 17 | 18 |

| Body | Disc | Security plate | Screw | O-ring | Spring washer |

| Ductile iron GJS-500-7 | Ductile iron GJS-500-7 | Stainless steel | Stainless steel A2 | EPDM rubber | Stainless steel A2 |

| 19 | 20 | 21 | 22 | 23 | 24 |

| Washer | O-ring | Nut | Washer | Screw | Screw |

| Zinc | EPDM rubber | Stainless steel A2 | Stainless steel A2 | Stainless steel A2 | Stainless steel A2 |

| 25 | 26 | 27 | 28 | 29 | 30 |

| Thrust bearing | Screw | End plate | Gasket | Shaft, stub | Safety key |

| Bronze | Stainless steel A2 | Ductile iron GJS-500-7 | EPDM rubber | Stainless steel AISI 420 | Stainless steel A2 |

| 31 | 32 | 33 | 34 | 35 | 36 |

| Screw | Screw | O-ring | Bolt | Washer | O-ring |

| Stainless steel A2 | Stainless steel A2 | EPDM rubber | Stainless steel A2 | Stainless steel A2 | EPDM rubber |

The range of WESDOM valves can be used for overground installation, in valve chambers and buried systems. It includes a full range of operating accessories and actuators.

WESDOM valves are installed all over the Asia,Africa continent, the Middle East and throughout Europe. They have justifiably acquired a faultless reputation for their durability, reliability and quality worldwide.

| DN | L | PN6/PN10/PN16 | PN6 | ||||||||

| H1 | H2 | H3 | L1 | L2 | L3 | D | D1 | d | n-do | ||

| 100 | 127 | 310 | 109 | 242 | 52 | 45 | 210 | 210 | 170 | 144 | 4–19 |

| 150 | 140 | 440 | 143 | 340 | 52 | 45 | 210 | 265 | 225 | 199 | 8–19 |

| 200 | 152 | 510 | 182 | 410 | 77 | 63 | 315 | 320 | 320 | 254 | 8–19 |

| 250 | 165 | 565 | 219 | 445 | 77 | 63 | 315 | 375 | 375 | 309 | 12–19 |

| 300 | 175 | 630 | 244 | 482 | 95 | 72 | 242 | 440 | 440 | 369 | 12–23 |

| 350 | 190 | 715 | 283 | 565 | 110 | 91 | 275 | 490 | 490 | 413 | 12–23 |

| 400 | 216 | 750 | 312 | 600 | 220 | 91 | 275 | 540 | 540 | 463 | 16–23 |

| 450 | 222 | 820 | 344 | 670 | 147 | 147 | 420 | 595 | 595 | 518 | 16–23 |

| 500 | 229 | 845 | 381 | 695 | 147 | 147 | 420 | 645 | 645 | 568 | 20–23 |

| 600 | 267 | 950 | 451 | 780 | 533 | 179 | 476 | 755 | 755 | 667 | 20–26 |

Tanzania Water Project

Main products:

Gate Valves, Butterfly Valves, Check Valves, Pipe Fittings, etc.

Client feedback:

The customer sent us the installation pictures of the WESDOM product in the working condition project, and the feedback quality is very good, and will maintain a long-term cooperative relationship with WESDOM;

Project pictures:

Application

①potable water supply pipelines and treatment plants.

②transportation of filtered and recycled water.

③irrigation distribution networks.

④water-pumping stations and hydroelectric plants.

⑤nuclear industry, fire safety and storage facilities.