Case

Home / Case / Experience / Applicable occasions of check valve

Case

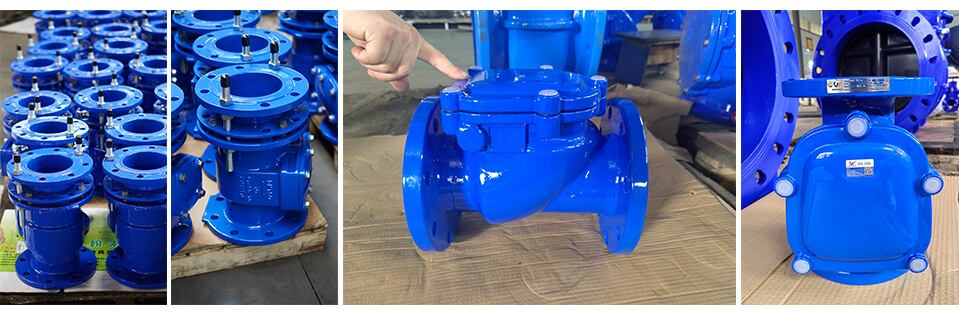

The purpose of using check valves is to prevent the backflow of the medium, generally at the outlet of the pump should be installed check valves. In addition, the outlet of the compressor should also be installed check valve. In short, in order to prevent the medium backflow, in equipment, devices or pipelines should be installed check valve.

Generally, in the nominal diameter of 50mm horizontal pipeline are selected vertical lift check valves. Straight lift check valves in the horizontal pipeline and vertical pipeline can be installed. The bottom valve is generally only installed in the pump inlet vertical pipeline, and the medium flows from bottom to top.

The swing check valve can be made into a very high working pressure, PN can reach 42MPa, and DN can also be made very large, the maximum can be more than 2000mm. According to the different materials of the shell and seals, it can be applied to any working medium and any working temperature range. The media are water, steam, gas, corrosive media, oil, food, medicine, etc. Medium working temperature range between -196~800℃.

Swing check valve installation position is not restricted, usually installed in the horizontal pipeline, but can also be installed in the vertical pipeline or inclined pipeline.

The butterfly check valve is suitable for low-pressure large diameter, and the installation of the occasion is restricted. Because the working pressure of the butterfly check valve can not be very high, but the nominal diameter can be very large, and can reach more than 2000mm, but the nominal pressure is below 6.4MPa. The butterfly check valve can be made into a clamp type, generally installed in the pipeline between the two flanges, using the form of a clamp connection.

The installation position of butterfly check valve is not restricted, it can be installed in the horizontal pipeline, and also can be installed in the vertical pipeline or inclined pipeline.

Diaphragm check valve is suitable for easy to produce water shock pipe, diaphragm can be perfect for eliminating to eliminate the medium against the flow of water generated by the shock and due to the diaphragm check valve working temperature and pressure by the diaphragm material restrictions, generally used in low-pressure room temperature pipeline, especially for water pipeline. General medium working temperature between -20 ~ 120 ℃, working pressure <1.6MPa, but the diaphragm check valve can be done to a larger calibre, DN can be up to 2000mm or more.

Diaphragm check valve because of its excellent waterproof performance, the structure is relatively simple, and low manufacturing costs, so in recent years more applications.

Ball check valve because the sealing member is rubber-coated ball, so the sealing performance is good, reliable operation, good resistance to water strikes; and because the sealing member can be a single ball, but also can be made into a multi-ball so that it can be made into a large caliberis . But its sealing member is rubber-covered hollow sphere, not for high-pressure pipeline, only for low-pressure pipeline.

Due to the spherical check valve shell material can be made of stainless steel, sealing the hollow sphere can be covered with PTFE engineering plastics, so in general corrosive media can also be applied to the pipeline.

The working temperature of this type of check valve is between -101~150℃, its nominal pressure ≤4.0MPa, nominal diameter range between 200~1200mm.