Case

Home / Case / Experience / Detailed introduction of knife gate valve

Case

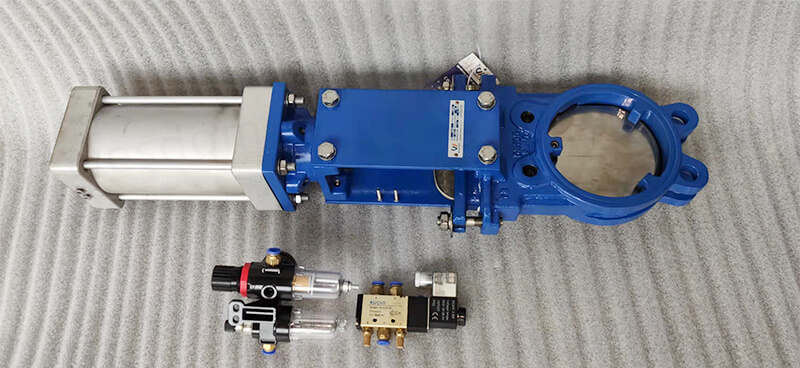

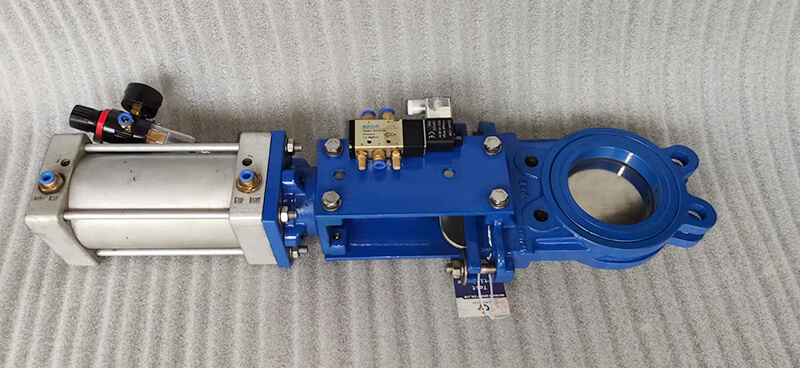

Knife gate valve is also known as mud valve. Its opening and closing part is a gate, and the movement direction of the gate is perpendicular to the direction of the fluid.The media is cut by a blade-shaped gate that cuts through fibrous materials.

Knife gate valve drive methods include manual, sprocket, electric, pneumatic, hydraulic, bevel gear, electric control hydraulic and gas-hydraulic drive. The shape of the knife gate valve is divided into two types: rising stem and non-rising stem. Knife gate valve materials include cast iron, cast steel, carbon steel, stainless steel, fluorine-lined, etc. Knife gate valve seals include hard seals, soft seals, single-sided seals, double-sided seals.

Ultra-thin knife gate valve with its small volume, small flow resistance, light weight, easy to install, easy to disassemble and other advantages completely solve the flow resistance of ordinary gate valve, flat gate valve, ball valve, globe valve, regulating valve, butterfly valve and other valves, heavy weight, difficult to install, cover an area of large problems. With the advent of knife gate valves, a large number of general purpose shut-off valves and regulating valves have been replaced by them.

Knife gate valves are used in the following areas:

1. Mining, coal washing, iron and steel industry - used for coal washing and washing pipelines, slag filtering and slurry pipelines, etc., ash discharge pipelines;

2. Purification device - used for waste water, mud, dirt and clarified water with suspended solids;

3. Paper industry - used for any concentration of pulp, material-water mixture;

4. Power station ash removal - used for ash slurry.