Case

Home / Case / Experience / How to deal with leakage from the ball valve grease nozzle?

Case

Grease injection maintenance is of great significance in reducing ball valve failures, extending the life of the ball valve, and making the ball valve easy to operate. The grease injection equipment injects grease (cleaning fluid) into the ball sealing system through the grease injection nozzle to maintain and maintain the ball valve. However, since the lower end of the grease nozzle is in the fluid pressure environment within the valve ball, it causes certain difficulties in handling and replacing the grease nozzle when it leaks.

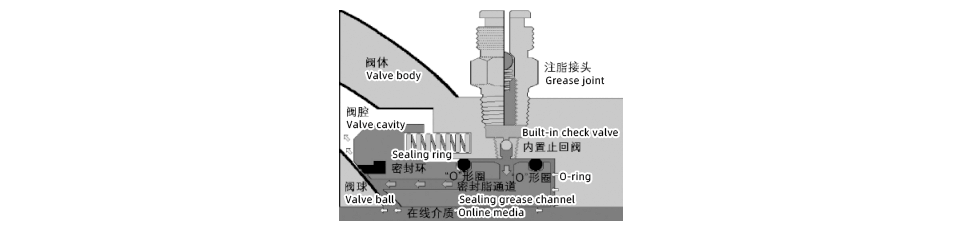

The seat sealing system of a typical ball valve is shown in Figure 1. A sealing pair is formed between the sealing ring embedded in the valve seat and the valve ball. The grease injection equipment passes the grease injection joint, the built-in check valve and the internal grease injection channel of the valve seat. Grease (cleaning fluid) is injected into the valve seat sealing ring position to achieve lubrication and sealing of the sealing pair. The lower end of the grease nozzle is directly connected to the valve body through threads, and the upper end is exposed to the atmosphere. The pressure between the upper and lower end surfaces of the grease nozzle is the pressure of the pipeline fluid. If the grease nozzle structure fails, fluid medium leakage will occur.

Most ball valves are designed with a built-in check valve after the external grease nozzle. The built-in check valve is directly screwed into the valve body and does not affect the grease joint. The purpose is to enable the external grease nozzle to be disassembled and replaced under online conditions. However, due to the small size and simple structure of the built-in check valve, this internal check valve is not completely reliable in actual work.

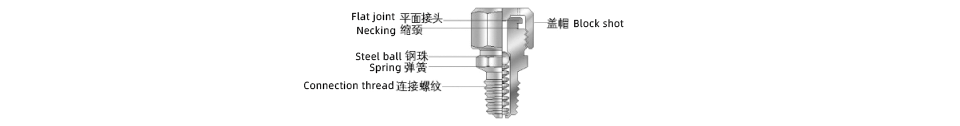

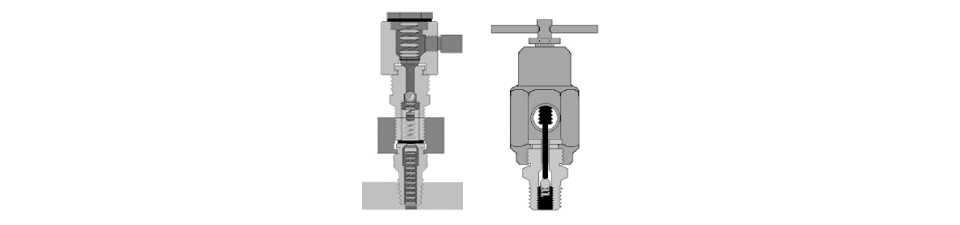

The grease nozzle generally consists of a cap, steel balls, springs and a body with connecting threads. The typical structure is shown in Figure 2 on the following page. From the structure, it can be seen that the grease injection joint generally adopts the bottom edge structure to limit the spring and steel balls in the grease injection joint body.

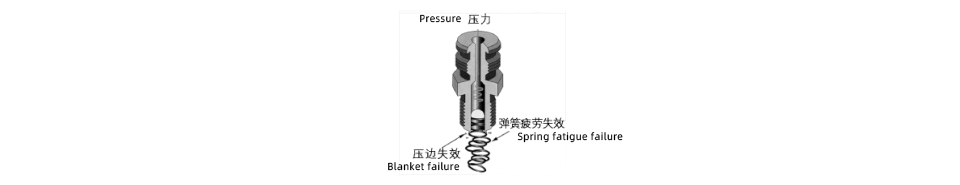

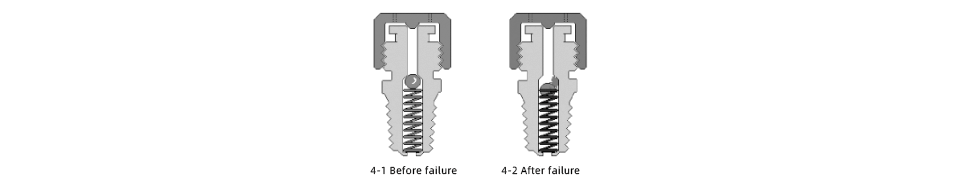

As shown in Figure 3 on the following page, blank holder failure and spring fatigue failure are important reasons for the failure of grease injection joints. As shown in Figure 4-1 on the following page, it is the structure of the grease injection nozzle before the failure; as shown in Figure 4-2, it is the check ball in the grease injection joint that was contaminated by dirt (sand, metal chips, solidified grease, etc.) It is stuck or the spring fails and cannot return to the original position, thereby losing the non-return function and causing leakage. In addition, there are other reasons such as damage to the check ball steel ball, which causes the grease nozzle to leak.

The valve seat grease joint is directly connected to the pipeline system. Evacuation of pressure from the valve cavity does not mean that it is safe to remove the grease nipple under pressure. Because even newly installed check valves are not safe and reliable. If the external grease fitting is removed from the valve body at this time, the pipeline pressure may blow off the external grease fitting through the grease passage through the failed internal check valve, causing serious consequences. If the check valve built into the grease joint fails, it will inevitably lead to a large amount of leakage. If it is in a valve room or building, it may cause emergency shutdown, fire or even explosion.

In high-pressure natural gas pipeline systems, most built-in check valves cannot effectively prevent small valve leaks. You can re-inject a small amount of cleaning fluid (or grease with good fluidity) into the valve sealing system, and after soaking for a period of time, this type of leakage can be effectively prevented. After the valve grease nozzle is injected with cleaning fluid, the solidified dirt around the ball and spring will quickly disintegrate or soften under the immersion of the cleaning fluid, allowing the check ball and spring to be reset, which can effectively prevent leakage. If the leakage of the grease nozzle is large, the grease injection operation will be difficult to perform. Therefore, before injecting cleaning fluid, a leakage self-locking adapter needs to be installed (as shown in Figure 5).

During the installation process, snap the top of the metal seal leakage locking joint onto the grease injection joint, and then twist the metal seal leakage locking joint clockwise to install the metal seal leakage locking joint onto the original grease injection nozzle.

Effective sealing performance can be obtained through gaskets or metal sealing rings. After the metal seal leakage locking joint is installed, a small amount of cleaning fluid, such as VAL-TEX2000 cleaning fluid, can be injected into the valve first. When the cleaning fluid contacts the check valve interface, leakage can be effectively stopped.

Before the check valve accurately falls into the valve seat, multiple greasing attempts with cleaning fluid (or grease with better fluidity) must be made. After the gas leakage stops, maintenance operators can still inject grease (or cleaning fluid) into the valve.

① The ball valve grease nozzle cannot be directly replaced online under pressure when it fails and leaks;

② When the grease injection nozzle leaks, injecting cleaning fluid and soaking it is a better early treatment method. If the leakage is large, the grease injection operation will be difficult to implement, and a leakage self-locking adapter needs to be installed before grease injection.