Case

Home / Case / Experience / What is the scope of application of knife gate valves?

Case

Knife gate valve, also known as knife gate valve, knife gate valve, slurry valve, slurry valve, its opening and closing member is the gate, the direction of movement of the gate is perpendicular to the direction of the fluid, by the knife edge-shaped gate that can cut fiber material to cut off the medium, the gate has two sealing surfaces, the most commonly used mode gate valve two sealing surfaces to form a wedge, wedge angle varies with the parameters of the valve, usually 5 °, wedge-type knife gate valve gate can be made into a the gate of the wedge-type knife valve can be made into a whole, called rigid gate; it can also be made into a gate that can produce a slight deformation to improve its craftsmanship and make up for the deviation of the sealing surface angle in the process, this gate is called a resilient gate.

The valve body does not actually exist in the chamber, the gate is lifted in the side guide groove and pressed against the seat by the bottom lug, if a high media sealing is required, the O-seal seat can be used to achieve a two-way seal. The knife gate valve has a small installation space, low working pressure, not easy to accumulate debris, and lower price.

Knife gate valve closed, the sealing surface can only rely on media pressure to seal, that is, rely on media pressure will be the sealing surface of the gate to the other side of the valve seat to ensure the sealing surface of the seal, which is self-sealing, most of the gate valve is used to force sealing, that is, when the valve is closed, to rely on external force to force the gate to the seat to ensure the sealing surface of the seal. This type of valve should generally be installed vertically in the pipeline.

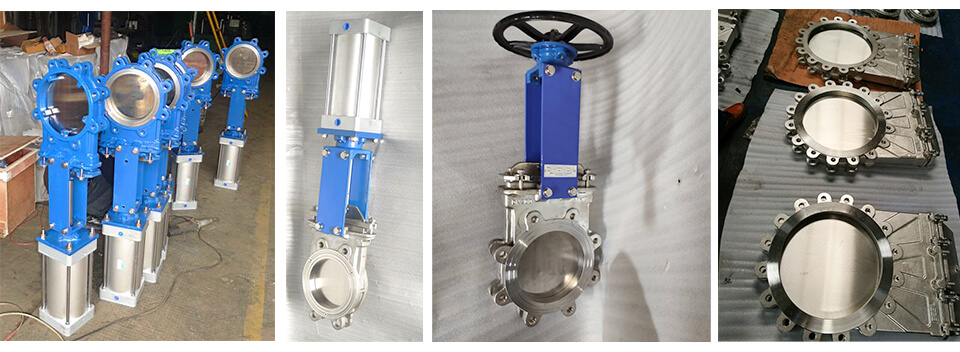

Knife gate valve drive mode: manual, sprocket, electric, pneumatic, hydraulic, bevel gear, electric-hydraulic and gas-hydraulic drive modes. Knife gate valve shape: open stem, concealed stem two. Knife gate valve material: cast iron, cast steel, carbon steel, stainless steel, fluorine lining, etc.

Ultra-thin knife gate valve with its small size, small resistance, light weight, easy to install, easy to disassemble and other advantages completely solved the common gate valve, flat gate valve, ball valve, globe valve, regulating valve, butterfly valve and other types of valve flow resistance, weight, difficult to install, covers an area of large and other difficult problems. Knife gate valve after the emergence of a large number of general cut-off class valves and regulating valves have been replaced by the.

1. mining, coal washing, steel industry - for washing coal pipelines, filter slurry pipelines, etc., ash discharge pipelines.

2. purification devices - for wastewater, slurry, dirt and clarified water with suspended matter.

3. paper industry - for any concentration of pulp, material-water mixture.

4. power station ash removal - for ash slurry.

1. Valve control can be done locally and remotely, also can realize remote position display and remote centralized control according to the user's requirements.

2. Light weight: the body is made of carbon steel, the weight is about 20%-30% lighter than the traditional gate valve, easy to install and maintain.

3. The use of this valve can improve the closing sealing performance of the conveying pipeline system and eliminate leakage to the maximum extent, which will play a positive role in promoting production efficiency and protecting the environment.

4. The sealing surface is made of highly wear-resistant, corrosion-resistant ceramic material, using inlay technology, with high corrosion resistance and good wear resistance, thus making the valve have a long life, and the cost performance ratio is 10 times higher than ordinary valves.

(1) Lifted gate sealing surface scrapes adhesion from the sealing surface and automatically cleans up debris.

(2) Stainless steel gate prevents sealing leakage caused by corrosion.

(3) Hard full gold sealing surface can ensure sealing wear resistance performance and requirements.

(4) No grooves on the sealing surface of the valve body, no accumulation of residue, can ensure flexible opening.

(5) Short structure length, can save raw materials, installation space also effectively support the strength of the pipeline.

(6) Scientific upper sealing stuffing box design, so that the upper seal is safe and effective, durable.

(7) Triangular shaped bracket saves material and ensures the required mechanical properties.

(8) The guide block on the valve body enables the correct movement of the gate, and the four squeeze blocks ensure the effective sealing of the gate.

(9) The reinforcement of the valve body is designed to improve the strength of the valve body.

(10) The stainless steel stem is durable and the double-headed bolt makes opening and closing more rapid.

(11) Optional drive mechanism is available.

(12) Above 150 calibre, fully enclosed structure, more effective in opening and preventing leakage.

(13) Fluorine rubber sealing surface can achieve sealing effect and improve the use of temperature.

(14) The rubber sealing surface is directly vulcanised in the valve body and will not fall off.

1. knife gate valve before installation shall check the valve cavity and sealing surface and other parts, do not allow dirt or sand adherence.

2. the bolts of each connection part, requiring uniform tightening.

3. check the packing parts require tightening, both to ensure the sealing of the packing, but also to ensure that the gate open flexible.

4. the user in the installation of the valve before, must proofread the valve model, connection size and attention to media flow direction, to ensure consistency with the valve requirements.

5. the user in the installation of the valve, must be reserved for the necessary space for the valve drive.

6. the wiring of the driving device must be carried out in accordance with the wiring diagram.

7. the knife gate valve must be regularly maintained, not arbitrarily collision and extrusion, so as not to affect the seal.