Case

Home / Case / Experience / Why is the pump outlet without a “check valve” prone to water hammer?

Case

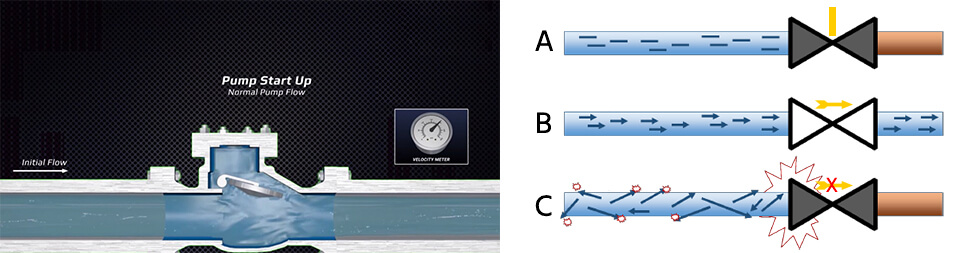

Water pump outlet pipe water flow due to open valves, valves and stop pumps and other sudden changes, causing sudden changes in the flow velocity of the pipe, resulting in a change in momentum per unit of time, is bound to produce the corresponding inertia force, thus causing a sharp rise in the pressure of the pipe and the sudden drop in the phenomenon of alternating changes. This water flow velocity and pressure with the time and position and the change of the phenomenon, known as water hammer (or water strike).

A different occurrence of water hammer happens when filling an empty pipe with water at high rates and the air is released through a small hole. When the air is completely out of the pipe, water flow is suddenly stopped, leading to a pressure surge.

Pumping station water hammer includes start-up water hammer, shutdown water hammer and stopping pump water hammer (formed due to sudden power failure etc.). The first two types of water hammer do not cause problems that endanger the safety of the unit under normal operating procedures. The latter forms a water hammer pressure value which is often very high and thus causes accidents.

(i) to draw up protective measures in the event that the maximum water hammer pressure causes damage to pipelines and units.

(ii) the development of protective measures in the event that the minimum water hammer pressure causes an impermissible negative pressure in the pipeline and damage to the pipeline as a result.

(iii) protection against damage caused by reversal of the unit.

In the pumping unit system, the characteristics of the pump that is used as a boundary condition at the beginning end of the pipeline, now we analyse the water hammer process (or hydraulic transition process) when the pump outlet is not fitted with a check valve and the pipeline outlet is not equipped with a flapper door, when the accident stops the pump, the pump loses its driving force, the gate valve on the pump outlet cannot be closed in time and the water in the pipeline flows backwards.

After the pump loses power, the speed of the pump drops sharply, the water flow in the pump and outlet pipe continues to move in the original direction due to inertia, but its flow speed decreases rapidly and the pressure drops until the water stops flowing in the positive direction and the flow rate is zero. In this moment, the pump is still positive rotation, the water flow for positive flow (from the pump to the direction of the water flow out of the pool is called positive flow), known as the pump working condition.

In the transient static water body with zero flow rate in the outlet pipe, a reverse water flow from the outlet pool to the pump is generated in the outlet pipe due to the action of the static head of the outlet pool. The reverse water flow acts as a brake to the pump impeller which is still in positive rotation, forcing the rotor speed of the unit to accelerate down until the speed is zero. At this instant, the pump outlet pressure gradually rises due to the resistance of the positive impeller to the reverse flow. The transient condition of the pump at this instant is called the braking condition.

With the increase of the reverse water flow, the pump speed from zero and began to reverse and rise rapidly, at the same time, the centrifugal force of the rotating impeller on the water flow also increases with the impediment to the reverse water flow. This resistance increases with the acceleration of the impeller reversal, causing the pressure behind the pump to rise rapidly, reaching a maximum at a certain point, and its corresponding reversal speed also reaches its maximum build. At the same time as the resistance increases, it also resists the continued increase of the flow in the reverse direction, and gradually decreases after reaching a certain maximum. The energy acting on the impeller also decreases accordingly, so that the reverse speed gradually decreases until, under the action of the stable static head, the torque acting on the impeller and the resistance torque of the rotating part of the unit are balanced, and the unit works like a hydraulic turbine with a constant reverse flow and speed without any load, and the water hammer pressure then disappears. This transient working condition is called the turbine working condition.

The above is the consequence of not having a check valve on the pump.

At the same time, the pressure change after the pump will be in the form of water hammer waves along the discharge pipe to the outlet pool orthogonal, and then reflected back from the outlet pool, in the outlet pipe to form a complex water hammer phenomenon, waterproof hammer phenomenon of the check valve products can be selected waterproof hammer check valve.