Case

Home / Case / Experience / DN2400 double eccentric butterfly valve

Case

The dn2400 double eccentric butterfly valve is designed by the company to develop the environmentally friendly, second eccentric spherical seal butterfly valve. Unpin connection loosen the adjustment ring to remove the pressure circle, sealing ring, and replace easily. Sealing ring designed on the body the structure is simple,the cover of the valve plate is the sphere of the ball , the opening and closing are frictionless and wear-resistant.

The dn2400double eccentric butterfly valve body valve plate and sealing ring with different materials can meet the requirements of different operating conditions.

All parts can be made of non-toxic epoxy powder electrostatic spraying, which can completely solve the valve's secondary pollution to the medium, which is an ideal choice for drainage industry.

The different materials are used to make the sealing ring of different materials, which can be adapted to different media, working conditions, and make the cost and performance to the best effect It can be driven by worm wheel and electric power.it is mainly used for food, water, beverage, chemical, medicine, etc.

Our company produces the double eccentric soft hearted sealing butterfly valve has simple structure, small flow resistance coefficient, difficult to stranded sundry drive torque is small, the advantages of simple operation,rapid, and it also has good flow regulating function and sealing performance at the same time, can achieve completely sealed, zero leakage gas test.

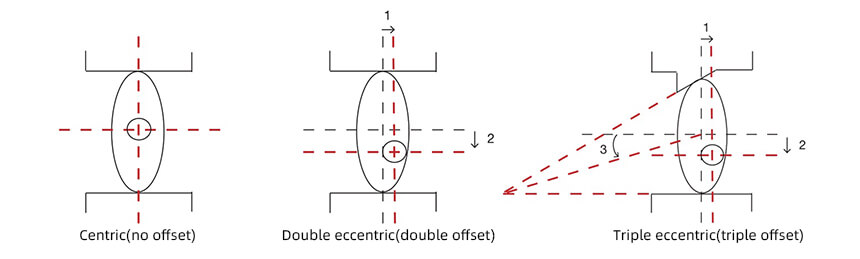

The butterfly valve can be centric or eccentric. On a centric (concentric) butterfly valve the stem is centered in the middle of the disc and the disc centered in the bore. The eccentric butterfly valve has one or more stems (stub shafts) located offset from the center according to the categories of double and triple offset valves.

Butterfly valves can be used for a broad range of applications within water supply, wastewater treatment, fire protection and gas supply, in the chemical and oil industries, in fuel handling systems, power generation etc. Some of the advantages for this type of valve are the simple construction not taking up too much space, and the light weight and lower cost compared to other valve designs.

Double-eccentric butterfly valve is suitable for the temperature <120℃

And nominal pressure≤1.6MPa less food, medicine, chemical, petroleum, electric power, textile,paper and other water supply and drainage, for adjusting flux on the gas pipeline and the role of intercepting medium. Its main features are:

1.Design novel, reasonable, structure unique, weight light open and close fast.

2.Small operation moment, convenient operation, easy to operate.

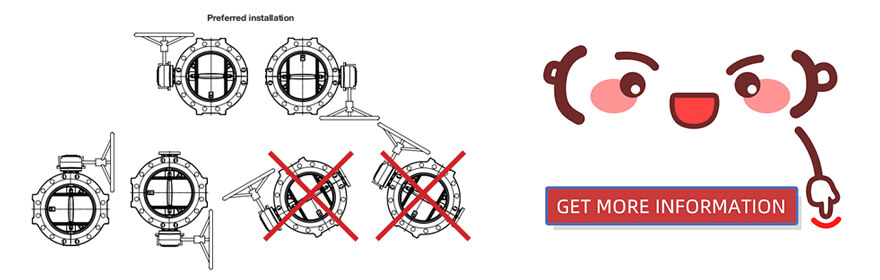

3.It can be installed and maintained in any position.

4.Seals can be replaced.The sealing performance is reliable and has a double seal zero leakage.

5.The sealing material is resistant to aging, corrosion and long life.

1.Check butterfly valve specification, pressure, temperature and corrosion resistance before installation. All parts should be checked for damage or loosening.

2.Butterfly valve can be installed on any angle of the pipe, should be closed installation; welding pipe flange should be the valve seal plate to prevent particles, debris contusion sealing surface, after welding remove the valve, valve sealing surface and pipe cavity cleaning, and then install fixed valve.

3.Before installation, clean the sealing surface (both ends sealing surface, butterfly plate sealing surface, seat sealing surface) thoroughly, remove dust and dirt.

4.Before installation, the butterfly valve should be empty, the opening and closing should be flexible, the opening and closing position should be in accordance with the pointer indication position

5.The butterfly plate must be in the closed position during installation to ensure that the butterfly plate does not collide with the pipe flange.

6.The opening position should be determined according to the rotation angle of butterfly valve butterfly plate.

7.Butterfly valve with bypass valve, open bypass valve before opening.

8.Install butterfly valves according to medium flow arrow

Double eccentric butterfly valves in all nominal widths can be installed with shafts in horizontal position (with gear facing upwards or downwards). A vertical position of the valve shaft is possible but it may affect the service life of the valve (number of operating cycles).