Case

Home / Case / Experience / Basic knowledge of expansion joints

Case

As an elastic compensation element, the expansion joint has the advantages of reliable operation, good performance, and compact structure. It has been widely used in chemical industry, construction, water supply, drainage, petroleum, light and heavy industry, refrigeration, sanitation, plumbing, fire protection, Basic engineering fields such as electric power play an important role in people's lives.

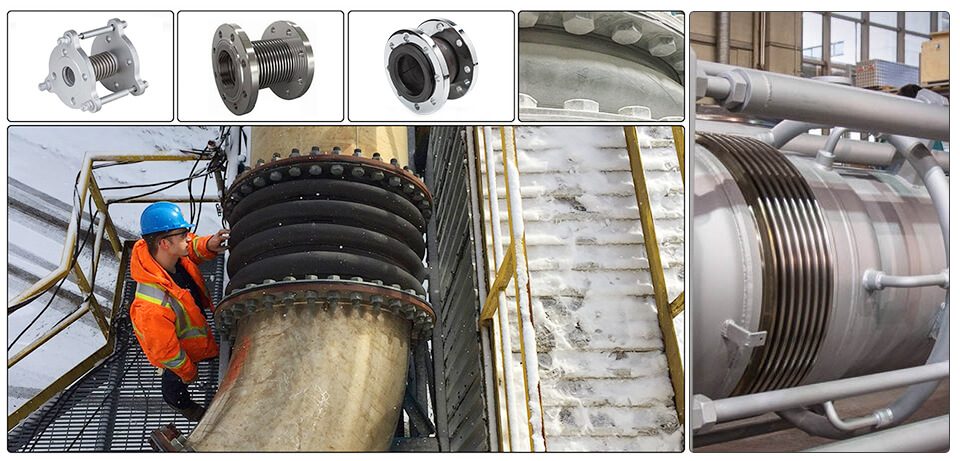

Expansion joints are customarily also called compensators, which are flexible structures arranged on container shells or pipes in order to compensate for additional stress caused by temperature differences and mechanical vibrations. Expansion joints are divided into: metal expansion joints and non-metallic expansion joints.

Under the same external dimensions, the compensation function of non-metallic expansion joints is much greater than that of metal expansion joints. Especially for the compensation function of lateral displacement, the compensation function of non-metallic expansion joints is almost an order of magnitude larger than that of metal expansion joints.

The expansion joint is like an elastic body, which will produce resistance after being shrunk or stretched. The resistance of metal expansion joints is much greater than that of non-metallic ones. This resistance is too large, which is not good for the system, and will damage the surrounding equipment.

The material of the non-metallic expansion joint not only has good high temperature resistance, but also has acid and alkali resistance. The yield limit of ordinary carbon structural steel is equal to zero in an environment of 600°C, and it will oxidize and peel if the temperature is higher. Carbon steel expansion joints are easy to crack during work, and stainless steel expansion joints will suffer from low-leakage corrosion in low-temperature environments, and their cost is also considerable.

The structure of the non-metallic expansion joint itself has thermal insulation performance. However, metal expansion joints do not have this condition. In order to keep warm, the outer layer of metal expansion joints is covered with an insulating layer.

Non-metallic expansion joints do not require maintenance during their normal service life; replacement of non-metallic expansion joints is much more convenient than metal expansion joints.

The service life of expansion joints is closely related to environmental conditions. Non-metal expansion joints have better wear resistance and corrosion resistance. Relatively speaking, the life of non-metal expansion joints will be longer than that of metal expansion joints under the same conditions.

Thanks to the flexible design and the special material used, the non-metallic expansion joint can withstand greater working pressure.

metal expansion joints is suitable for liquids, gases, and powders. Non-metallic expansion joints can be either gas or liquid.

are an important category of non-metallic expansion joints. They have large displacement compensation capabilities, and can compensate axial, lateral and angular displacements. They can reduce noise, reduce vibration and have certain anti-corrosion capabilities.

1. Carbon steel and low alloy corrugated expansion joints are only suitable for t≤375°C; austenitic stainless steel corrugated expansion joints are suitable for t≤500°C.

2. For corrugated expansion joints made of carbon steel or low alloy steel, the corrosion margin shall not exceed 1mm, otherwise austenitic stainless steel should be used.

For mediums that are prone to corrosion such as chlorides, sulfides, acids, and alkalis, or when the working temperature is high (over 550°C), corrosion-resistant alloys or high-temperature alloys should be used to manufacture expansion joints, such as domestic materials FN-2, NS111 and B-315 or Incoloy800, 825, etc.

Pipeline expansion joints are mainly divided into three types according to their structural forms: elbow expansion joints, bellows expansion joints and casing expansion joints.

The elbow type expansion joint bends the pipe into a U shape or other shapes, and uses the elastic deformation capacity of the shape to compensate. Its advantages are good strength, long life, and can be made on site. The disadvantages are that it takes up a lot of space, consumes a lot of steel and has high frictional resistance. This expansion joint is widely used in various steam pipelines.

The bellows expansion joint is an expansion joint made of metal bellows. It can expand and contract along the axial direction, and also allows a small amount of bending, which is used for axial length compensation on the pipeline. When in use, protective rods or protective rings are provided at both ends of the corrugated pipe, and guide brackets are provided on the pipes at both ends connected with it. In addition, there are corner and transverse expansion joints, which can be used to compensate the corner deformation and lateral deformation of the pipeline. The advantage of this type of expansion joint is that it saves space and materials, and is convenient for standardization and mass production. The disadvantage is that the service life is short, and it is generally used on pipelines with low temperature and pressure and short length.

Joint The casing expansion joint is composed of inner and outer casings capable of axial relative movement, and a stuffing box is used to seal the inner and outer casings. When in use, keep the pipes at both ends moving on one axis, and install guide brackets at both ends of the telescopic joint. Its advantages are small frictional resistance to fluid flow and compact structure; its disadvantages are poor sealing and large thrust on the fixed bracket. Casing expansion joints are mainly used for water pipes and low-pressure steam pipes.