Case

Home / Case / Experience / Which media should use vortex flowmeter?

Case

With the development of modern industrial production, enterprises pay more and more attention to energy requirements. Process control, production costing, energy measurement, and flow measurement assessment are increasingly dependent on, so accurate measurement of the media flow in the industrial energy saving is increasingly important.

Wesdom's vortex flowmeter has comprehensive absorption of advanced technology and experience in developed countries, with advanced circuitry, low power consumption, wide range ratio, simple structure, resistance loss is a small, durable, wide range of uses, long service life, stable, easy to install and debugging, maintenance of a small amount of features, to solve the problem of energy measurement better.

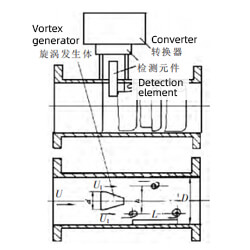

Set up in the fluid vortex generator (resistance fluid), the vortex generator on both sides of the vortex alternately produces a regular vortex. This vortex is called Carmen vortex street, as shown in the figure.

Kamen vortex and vortex flow meter

A vortex flowmeter is mainly used for industrial pipeline media fluid flow measurements, such as gases (vapor, compressed air), liquids (non-conductive liquids: thermal oil, distilled water, a variety of low-viscosity pure oils, a variety of non-conductive, non-corrosive, pure chemical liquids) and other media.

#1 Small pressure loss, large range, and high accuracy in measuring the volume flow condition are almost independent of the fluid density, pressure, temperature, viscosity, and other parameters. 2. No moving mechanical parts, so high reliability, low maintenance, and simple and solid structure are very reliable for long-term operation.

#2 No moving mechanical parts, so high reliability, low maintenance, simple and solid structure, and long-term operation is very reliable.

#3 Simple installation and maintenance are very convenient.

#4 The detection sensor does not come into direct contact with the medium, has stable performance, and has a long service life.

#5 The output is proportional to the flow rate of the pulse signal, with no zero drift, high accuracy, and convenient computer networking.

#6 Wide measuring range, range ratio up to 1: 10.

#7 Small pressure loss, low operating costs, more energy-saving significance.

Failure 1:

Failure phenomenon: Newly installed or overhauled vortex flowmeter installed in the field, showing that the instrument does not indicate.

Cause analysis: No flow in the pipeline or flow is very small, no vortex generated within the sensor; sensor detection sensitivity is too low; probe and pipe wall between the debris stuck.

Failure 2:

Failure phenomenon: No fluid flow in the pipeline, and the display instrument has a flow display.

Reason analysis: Poor grounding of the instrument to introduce external interference; sensor sensitivity is too high.

Failure 3:

Failure phenomenon: Flow rate display meter swing.

Reason: Amplifier sensitivity is not properly adjusted; incorrect installation of the meter, causing vibration of the medium passing through the meter.

Fault 4:

Fault: The secondary indicator is low and slow.

Reason: Dirt may be blocked between the probe and the inner wall, but it is not blocked.

Failure 5:

Failure phenomenon: A power meter on the indication of a scale, and no matter how to adjust the sensitivity potentiometer does not work.

Reason analysis: Generally may be a table within a component damage.

Indication of long-term inaccuracy, always no indication, the indication of a wide range of fluctuations can not be read, the indication does not return to zero, no indication of small flow, and the instrument coefficient can not be determined.

#1 Selection problems.

Vortex flowmeter in the caliber selection and design selection, due to changes in process conditions, the phenomenon of selecting large specifications. In the actual selection should choose the smallest possible caliber to improve measurement accuracy. Improper selection may result in an indication of long-term inaccuracy. Indication of large fluctuations can not be read.

#2 Installation problems.

The sensor before and after the length of the straight section is not long enough, which will also cause the indication of long-term inaccuracy.

#3 Secondary instrumentation problems.

Common secondary instrumentation problems include short circuit boards, range setting of individual display bad, and K factor setting of individual position display bad, so it is impossible to determine the range setting and other parameter settings, resulting in an inaccurate indication of the instrument.

#4 Circuit wiring problems.

Connections are not properly connected, resulting in interruption of the circuit, so the instrument always has no instructions.

#5 The connection between the secondary instrument and the subsequent instrument.

Problems with the subsequent instrument or the subsequent instrument maintenance caused by the secondary instrument output current signal open circuit, resulting in the secondary instrument having no indication.

#6 The use of environmental problems.

Due to high humidity and wet circuit boards, sensors installed in the well may also cause the instrument indication to be inaccurate or have no indication fault. The way to deal with the vortex flowmeter probe is regularly cleaned, check the grounding and shielding, regular drying, or moisture-proof treatment.

We look forward to working with you!

To learn more about our products, please contact:

WhatsApp: +86 13849184495

eileen@wsdsolution.com