Case

Case

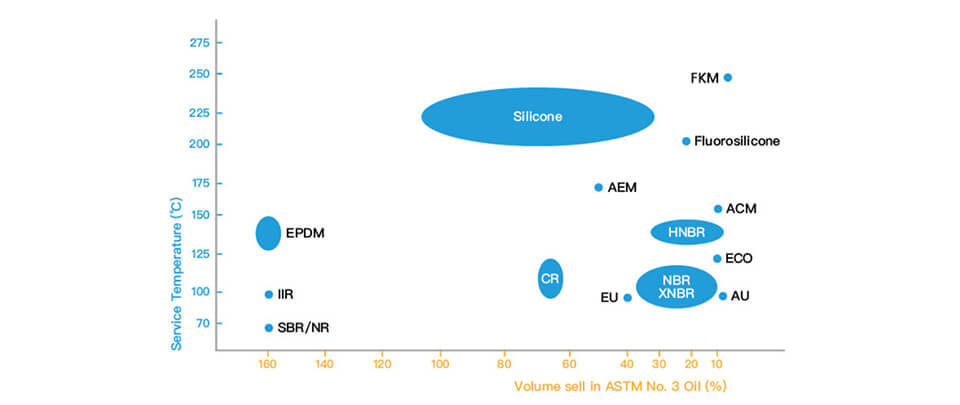

Fluoroelastomer is a well-known high-performance rubber with excellent resistance to high temperatures, ozone, weather, oxidation, mineral oils, fuel oils, hydraulic fluids, aromatics and many organic solvents and chemicals.

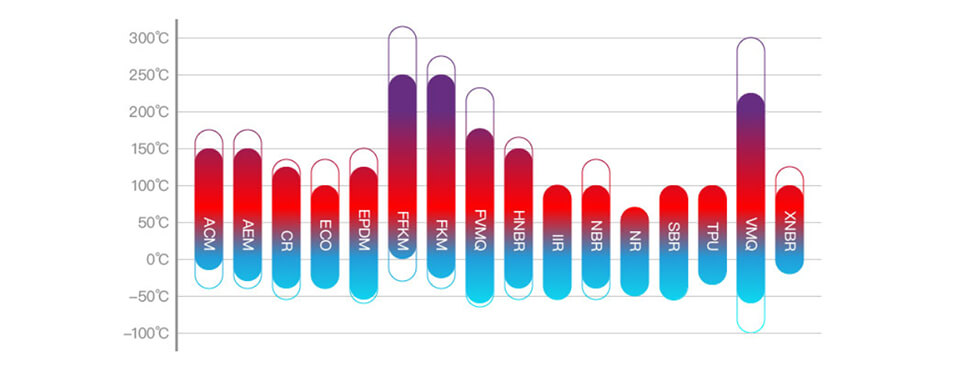

Static Seal: -26℃ ~ 232℃, up to 275℃ for a short period of time. Although they can still be used for a short period of time at a temperature of 275℃, their service life will be shortened when the temperature exceeds 250℃.

Dynamic Seal: -15°C ~ 200°C

FKM is commonly used in the automotive, chemical, aerospace and many other industries due to its excellent resistance to high temperatures, oils, solvents, flames, chemicals and weather.

Neoprene rubber is one of the first elastomers successfully synthesised by Dupont in 1931. Neoprene is a copolymer of chlorine and butadiene. Neoprene has good ozone, weather, chemical and aging resistance. It also has good mechanical properties, flame retardancy and good low-temperature elasticity.

Temperature range: -40℃ ~ 100℃, short time to 125℃.

Neoprene is used in thousands of different environments, including automotive, wire and cable sheathing.

Butadiene-acrylonitrile copolymers are also known as Nitrile Rubber (NBR). The amount of acrylonitrile in the NBR molecule is variable (18% - 50%) and affects the properties of the finished material.

The higher the acrylonitrile content, the better the resistance to lubricants and fuel oils, but the low-temperature elasticity and compression set deteriorate. The lower the acrylonitrile content, the better the low-temperature resistance, but at the same time sacrifices the oil resistance at high temperatures. Given these relative relationships, the compromise is a rubber with a medium acrylonitrile content. Compared to other elastomers, NBR has good mechanical properties and high friction resistance.

NBR is not as resistant to weathering and ozone. Special formulations are available to improve this, or NBR/PVC blends can be used to provide excellent weathering, ozone, and fuel resistance.

Temperature Range:

General grade: -40 ~ 100°C

Low temperature grade: -55 ~ 100℃ (TR10: -41.5℃)

High Temperature Resistant Grade: -30 ~ 125℃ (Air)

-30 ~ 150°C (oil)

NBR formulations offer excellent resistance to friction, non-polar oils and solvents, water and osmosis (higher acrylonitrile content is preferred).

NBR can also be used to dilute acid, alkaline and salt solvents at low temperatures.

NBR is not suitable for aromatic hydrocarbons, chlorinated hydrocarbons and polar solvents.

EPDM is a terpolymer consisting of ethylene and propylene, plus trace amounts of a third monomer (usually a diolefin) to provide the vulcanisation of the rubber. General ethylene propylene rubber has excellent resistance to ozone, heat and weathering, good elasticity at low temperatures, good chemical resistance (e.g., many dilute acids, alkalis and polar solvents), and also has excellent insulating properties.

Temperature range: -55 ~ 125 ℃ (TR10: -46.1 ℃), using organic peroxide vulcanisation can be as high as 150 ℃.

EPDM rubber has a wide range of applications in the automotive industry, where it is a good choice for sealing parts in phosphate-ester-based hydraulic fluids and glycol-based brake fluid systems.

For household water use, rubber parts must pass chloramine and chlorine resistance tests, which are not applicable to all EPDMs, with higher saturated EPDM and higher ethylene content offering better resistance to chloramine and chlorine attack. It is also commonly used in hot water or vapour at temperatures up to 150 °C.

Perfluoroelastomer FFKM, or perfluoroether rubber, is often confused in the market with the trade names of various suppliers. For example, DuPont's Kalrez™ rubber series has been confused with perfluoroelastomer FFKM, which is in fact the manufacturer's trade name rather than the name of the compound, and there is no equivalence between the two.

In terms of molecular structure, unlike fluoroelastomer FKM, perfluoroelastomer FFKM is composed of a molecule in which all of the carbon atoms in the main chain or side chains are bonded to fluorine atoms. It has a higher fluorine content than FKM, and the fluorine content of perfluoroelastomer FFKM is between 74-76%.

Because of the higher fluorine content than FKM, PERFKM has the best temperature and chemical resistance among all elastomers.

Temperature range: -25 ~ 250°C

Special grades can be sealed at 330 degrees Celsius. It is also resistant to strong acids, alkalis, ethers, ketones, esters, nitrogen-containing compounds, hydrocarbons, alcohols, aldehydes, oils, vapours, amine-based compounds and other chemical products. Therefore, it is widely used in semiconductor plants or pipeline seals in the petrochemical industry.

Perfluoroelastomer FFKM also has excellent airtightness, with vacuum resistance up to 1.33X10^-7~1.33X10^-8 pa, but the disadvantage is that the price is high, and it has been used in more severe use environments.

In addition, high cleanliness perfluoroelastomer, with its extremely low outgassing and no filler, no contamination of samples or with the environment of acids, alkalis, gases, or plasma interaction concerns, to meet the semiconductor needs of a variety of etching processes, and is widely used. In the more difficult environment, perfluoroether rubber FFKM excellent sealing and resistance, the more it can play and work with various industries.