Case

Home / Case / Experience / The main factors affecting the sealing performance of the flange

Case

An important factor affecting the seal. The preload must compress the gasket to achieve the initial seal. Appropriately increase the bolt preload can increase the sealing ability of the gasket, because increase preload can make the gasket in the normal operating conditions to retain a larger contact surface specific pressure. However, the preload should not be too large, otherwise it will make the gasket overall yielding and loss of resilience, or even the gasket will be extruded or crushed. In addition, the preload force should be as uniform as possible on the gasket. Usually take to reduce the bolt diameter, increase the number of bolts, take the appropriate pre-tightening method and other measures to improve the sealing performance.

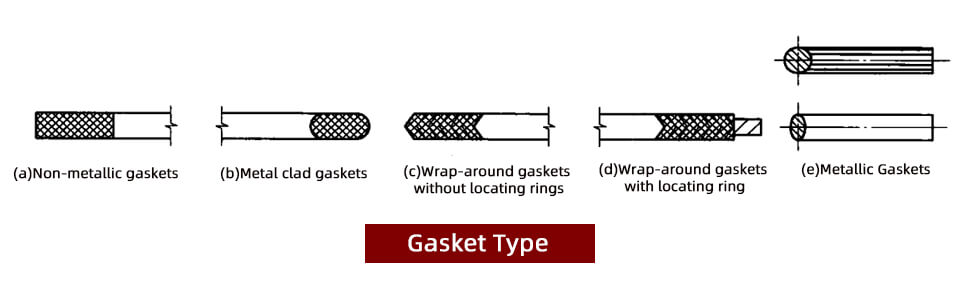

Gasket is an important element that constitutes a seal, the main types are shown in the figure below.

The role of the gasket is to seal the gap between the sealing surfaces of the two flanges to prevent fluid leakage. Types of gaskets include non-metallic gaskets, combined non-metallic and metallic gaskets and metallic gaskets. Suitable gasket material requirements gasket in the appropriate preload under the action of both can produce the necessary elastic deformation, but not be crushed or extrusion; work flange sealing surface of the distance is stretched, the gasket material should have enough rebound capacity, so that the gasket surface and flange surface in close contact, in order to continue to maintain good sealing performance; selection of the gasket material should also be taken into account the working medium and working temperature. The width of the gasket is also an important factor affecting the sealing, the wider the gasket, the greater the required preload, and thus the larger the bolt and flange size requirements.

①Nonmetallic gaskets such as rubber, asbestos rubber, PTFE, etc. are commonly used on medium and low pressure equipment and pipeline flanges, which have better corrosion resistance and flexibility, but poorer strength and temperature resistance. They are usually cut from the whole gasket sheet, the whole gasket shape is a circle, the cross-section is rectangular.

② In order to improve the strength and heat resistance of the gasket, a thin steel strip and asbestos tape (or PTFE tape or flexible graphite tape) together with the winding made of twisted gaskets or asbestos or other non-metallic materials outside the metal sheet made of metal-clad gaskets, with multi-channel sealing effect, and good resilience, used in higher temperatures and pressure ranges, and can be in the pressure, temperature fluctuations in the conditions to maintain good sealing, and therefore is widely Adopted.

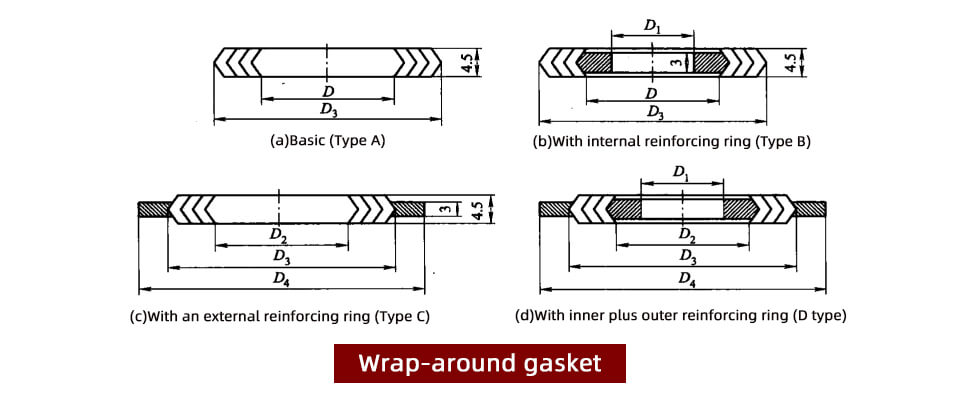

Winding gaskets are made by winding a steel strip with asbestos or PTFE or flexible graphite filler strips. To prevent loosening, the beginning and end of the metal strip are welded. In order to increase the elasticity and resilience of the gasket, metal and non-metallic tape are rolled into a wave. There are two kinds of wave shapes: V-shape and W-shape.

Type A - also known as the basic type, without a reinforcing ring, for tongue and groove sealing surface.

Type B - with internal reinforcement ring, used for concave and convex sealing surfaces.

Type C - with external reinforcing ring, used for flat sealing surface.

Type D - with internal and external reinforcing rings, used for flat sealing surfaces.

Metal clad gasket is composed of asbestos rubber sheet as inner core and thin metal sheet with thickness of 0.2~0.5mm (as shown below).

The material of metal plate can be aluminium, steel and its alloys, stainless steel or high quality carbon steel can also be used. Metal clad gaskets are also used only on the two types of flanges, B flat welding and long neck butt welding.

④ On the flanges of high-pressure equipment and pipelines, metal gaskets are commonly used, and the materials are soft aluminium, copper, soft steel and stainless steel. In addition to the rectangular cross-section of the metal gasket, there are also cross-sectional shape of the oval or octagonal and other special shapes of the metal ring gasket. When the operating pressure is very high or the leakage rate requirements are very strict, plus the temperature is very high or extremely corrosive, metal gaskets can be used. Metal gasket specific pressure value is very large, in order to reduce the bolt force, the compression surface must be very narrow, relying on the very narrow compression surface to maintain good sealing, must have a small surface roughness, Ra ≤ 2.5μm to Ra ≤ 0.63μm.

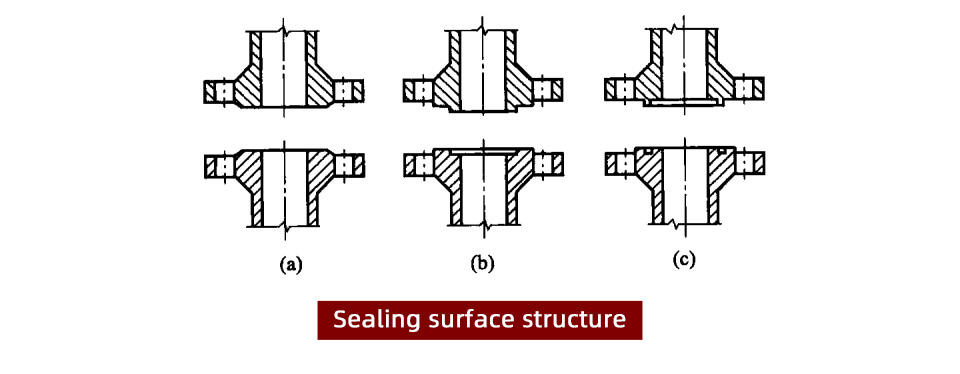

Between the flange into the gasket and press and play a sealing role in the contact surface is called flange sealing surface or pressure surface, sealing surface type selection and operating conditions, the consequences of leakage and the nature of the gasket, the most common structural types are as follows.

① Plane sealing surface: its structure is shown in the following figure (a), the sealing surface is not a smooth plane, in the plane is often open 2~4 concentric circles distributed triangular cross-section grooves (i.e., flange waterline).

Plane sealing surface structure is simple, easy to manufacture, easy to carry out anti-corrosion lining. Secondly, the width of the sealing surface of this structure is larger, so the use of non-metallic or metal soft gasket is often used. However, after the bolt is tightened, the gasket material is easy to stretch to both sides. Used for the required compression force is not high, and the medium is non-toxic occasions.

② Concave-convex sealing surface: the structure of the sealing surface as shown in the following figure (b), it is equivalent to a pair of plane sealing surface of the flange, one of which is made with a raised platform of the compression surface, and this flange is called the convex flange, another corresponding to make a concave surface is called a concave flange, and concave size exactly the same size of gasket embedded in it, the gasket is easy to centre. The height of the raised plane is slightly greater than the depth of the concave surface, and the gasket is sealed by bolts.

This structure can limit the radial deformation of the gasket, can prevent the gasket from being extruded, to a certain extent, will improve the sealing performance. Applicable to higher pressure occasions.

③ Tongue and groove sealing surface: in the middle of a pair of plane sealing surface width direction, one of them is made into a cross-section such as tongue and groove, another cross-section such as groove compression surface paired, as shown in the following figure (c), the former is known as tongue and groove flange, the latter is known as groove flange.

Groove type compression surface can limit the radial deformation embedded in the gasket, sealing performance is good, at the same time, the gasket can be less subject to the medium of scouring and corrosion. However, the tongue and groove part is easy to destroy. Commonly used in flammable, explosive, toxic media and higher pressure occasions.

There are also trapezoidal groove sealing surface and conical sealing surface. The former with oval cross-section ring metal gasket, the latter with a lens type ring metal gasket. The above two structures are forced sealing, commonly used in high-pressure pipelines.

The form and surface properties of the flange sealing surface play a vital role in the sealing effect. The straightness of the flange sealing surface, the perpendicularity between the sealing surface and the flange centre line directly affects the uniformity of the gasket force and the good contact between the gasket and the flange. The roughness of the flange sealing surface should match the requirements of the gasket. The surface is not allowed to have radial knife marks or scratches, not to mention the existence of surface cracks.

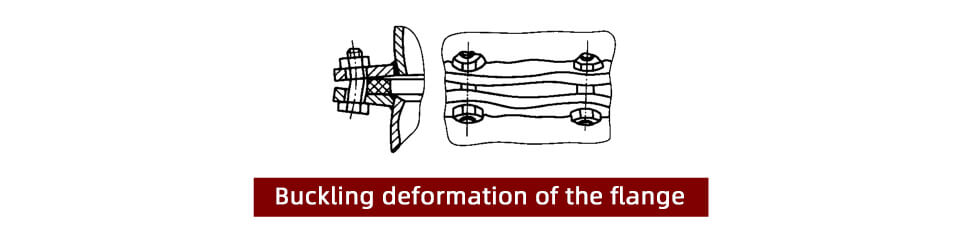

Excessive warping deformation due to insufficient flange stiffness (as shown below) is often one of the main reasons for sealing failure of bolted flange connections in actual production. The flange with large stiffness has small deformation, which can transfer the bolt preload to the gasket uniformly, thus improving the sealing performance of the flange.

Flange stiffness and many factors, including an appropriate increase in the thickness of the flange ring, reduce the bolt centre circle diameter and increase the outer diameter of the flange ring, can improve the flange stiffness, the use of necked flange or increase the size of the conical neck part, can significantly improve the flange's bending capacity. However, unprincipled increase in flange stiffness will make the flange become bulky and heavy, and increase the cost.

Pressure, temperature and the physical and chemical properties of the medium on the sealing performance of the impact is very complex, simple pressure and medium on the sealing of the impact is not significant, but in the combined effect of temperature, especially fluctuations in high temperature, will seriously affect the sealing performance, and even make the seal due to fatigue and complete failure. Because at high temperatures, the viscosity of the medium is small, permeability, easy to leak; medium on the gasket and flange corrosion intensified, increasing the possibility of leakage; flange, bolts and gaskets will produce a large high-temperature creep and stress relaxation, so that the seal failure; some non-metallic gaskets will also accelerate the aging, deterioration, and even burnt.