Case

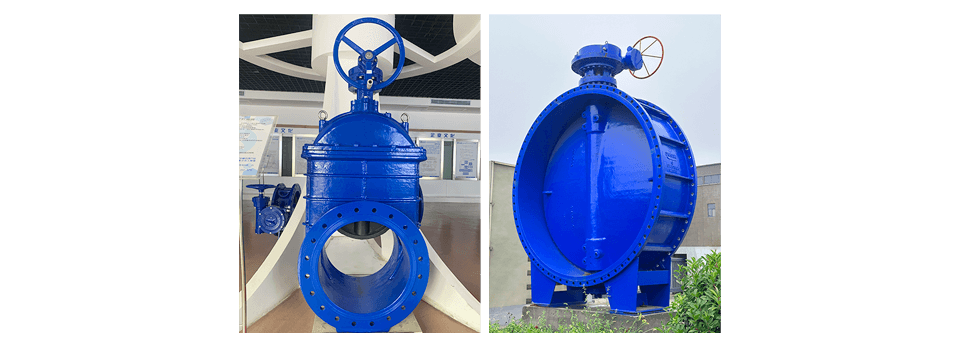

Home / Case / Experience / You don’t know how to choose butterfly valves and gate valves!

Case

In the water supply pipeline network, in order to reduce the soil covering depth of pipelines, butterfly valves are generally selected for larger diameter pipes. If the soil covering depth is not much affected, gate valves are selected. However, the price of gate valves of the same specifications is higher than that of butterfly valves. As for the dividing line of caliber, it should be considered on a case-by-case basis. Judging from the feedback from customers on the use of valves in the past two decades, butterfly valves have more failures than gate valves. Therefore, it is worthy of attention to expand the use scope of gate valves when conditions permit.

Regarding gate valves, in recent years, many domestic valve manufacturers have developed and imitated soft-sealing gate valves. Compared with traditional wedge-type or parallel double-gate gate valves, this kind of gate valve has the following characteristics:

① The valve body and valve cover of the soft-sealing gate valve are cast by precision casting. They are formed in one step and basically do not need mechanical processing. They do not use sealing copper rings, saving non-ferrous metals.

② There are no pits at the bottom of the soft-sealed gate valve and no accumulation of slag. The failure rate of the gate valve opening and closing is low.

③ The soft-sealed rubber-lined valve plate has uniform dimensions and is highly interchangeable.

④ However, when opening and closing the soft-sealing gate valve, it must not be closed too far, as long as the water-stopping effect is achieved, otherwise it will not be easy to open or the rubber lining will peel off.

According to the functions and uses of gate valves and butterfly valves, gate valves have small flow resistance and good sealing performance. Because the gate valve plate and the flow direction of the medium are at a perpendicular angle, if the gate valve does not open or close the valve plate in place, the erosion of the valve plate by the medium will cause the valve plate to vibrate. , it is easy to damage the gate valve seal.

Butterfly valve, also called flap valve, is a regulating valve with a simple structure that can be used for switching control of low-pressure pipeline media. The butterfly valve refers to a closing member (valve disc or butterfly plate) that is a disc and rotates around the valve axis to open and close. A kind of valve, the valve can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil, liquid metal and radioactive media. It mainly plays the role of cutting and throttling on pipelines. The butterfly valve opening and closing part is a disc-shaped butterfly plate that rotates around its own axis in the valve body to achieve the purpose of opening and closing or adjustment.

The butterfly plate is driven by the valve stem. If it is rotated 90°, it can complete one opening and closing. By changing the deflection angle of the butterfly plate, the flow rate of the medium can be controlled.

Butterfly valves are suitable for pipelines transporting various corrosive and non-corrosive fluid media in engineering systems such as generators, coal gas, natural gas, liquefied petroleum gas, city gas, hot and cold air, chemical smelting and power generation environmental protection, building water supply and drainage, etc. Used to regulate and cut off the flow of media.

The gate valve is a gate that opens and closes. The movement direction of the gate is perpendicular to the direction of the fluid. The gate valve can only be fully open and fully closed, which varies according to the door parameters, usually 5°, when the medium temperature is not high. is 2°52'. To improve its craftsmanship and compensate for the deviation of the sealing surface angle during the processing, this type of gate is called an elastic gate.

When the gate valve is closed, the sealing surface can be sealed only by the medium pressure, that is, the sealing surface of the gate plate is pressed to the valve seat on the other side by the medium pressure only to ensure the sealing of the sealing surface. This is self-sealing. Most gate valves adopt forced sealing, that is, when the valve is closed, external force must be relied on to force the gate plate to the valve seat to ensure the sealing performance of the sealing surface.

The gate plate of the gate valve moves linearly with the valve stem, which is also called a rising stem gate valve. Usually there is a trapezoidal thread on the lift rod. Through the nut on the top of the valve and the guide groove on the valve body, the rotational motion is changed into linear motion, that is, the operating torque is changed into the operating thrust. When the valve is opened, when the lift height of the gate plate is equal to 1:1 times of the valve diameter, the fluid channel is completely unobstructed, but during operation, this position cannot be monitored.

In actual use, the top of the valve stem is used as a mark, that is, the position that does not open, as its fully open position. In order to consider the locking phenomenon caused by temperature changes, the valve is usually opened to the top position and then retracted 1/2-1 turn as the fully open valve position. Therefore, the fully open position of the valve is determined by the position of the gate (i.e. stroke).

Some gate valve stem nuts are located on the gate plate. The rotation of the handwheel drives the valve stem to rotate and lift the gate plate. This type of valve is called a rotating rod gate valve or a concealed rod gate valve.