case

case

We have always abided by our commitment to partnerships, meeting or exceeding the requirements of each customer.

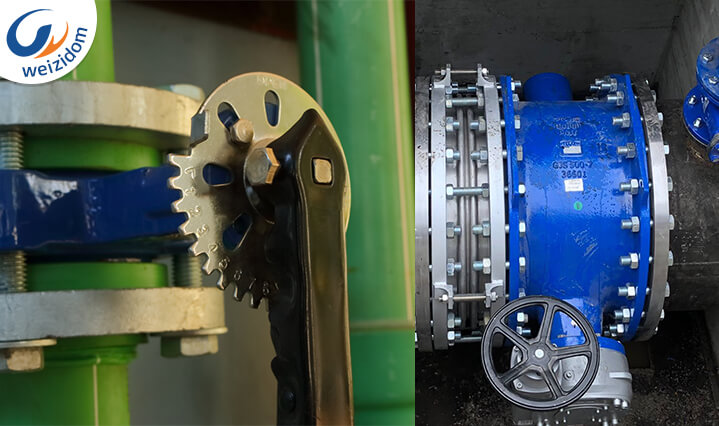

A flange adaptor is an essential component used to connect two different pieces of equipment, such as pipes, valves, or other mechanical systems, that have different flange types, sizes, or specifications.

A PVC valve is a valve made of polyvinyl chloride (PVC) material, characterized by corrosion resistance, lightweight, and low cost. It is widely used in various non-high-temperature and non-high-pressure fluid transport systems, particularly in chemical, water supply and drainage, environmental protection, and water treatment industries.

Flanged Ultrasonic Water Meter A flanged ultrasonic water meter is…

With the continuous application of new chemical materials and the…

Whether it is a butterfly valve, a gate valve, or other valves, whether they are in use or not in use, routine maintenance is required. Firstly, to ensure that the valve can be used normally without failure, and secondly, to extend the service life of the valve.

As a core device in industrial flow measurement, improper selection of an electromagnetic flowmeter can lead to up to 50% in maintenance cost waste.

In industrial piping systems, Wafer Type Butterfly Valves and Flanged Butterfly Valves are the two most common valve types. However, confusion between their differences often leads to leaks, cost inefficiencies, and safety risks.

Definition and Core Value of Electromagnetic Flowmeters An electromagnetic flowmeter…

Check Valve (Non-Return Valve) A check valve, also known as…