Case

Home / Case / Experience / What should we do if the control valve packing leaks?

Case

The control valve is one of the terminal control components of the automatic control system. Because there are many high temperature and high-pressure working conditions in the chemical plant, some media are highly corrosive and toxic and are flammable and explosive.

When the valve packing leaks, not only It will cause waste of raw materials, and will also cause serious pollution to the environment, and even cause fire, explosion, poisoning, and other life-threatening safety accidents.

Therefore, enough attention should be paid to the problem of control valve packing leakage, and it is very important to select the sealing packing reasonably in the design and selection. For the packing seal of the control valve, combined with years of work experience and relevant information, through the analysis of the structure of the control valve stuffing box, the characteristics and applications of PTFE and flexible graphite packing are introduced, and the packing of the control valve is reasonably selected. Give a brief introduction.

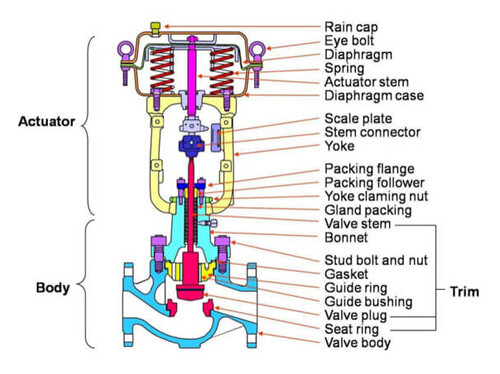

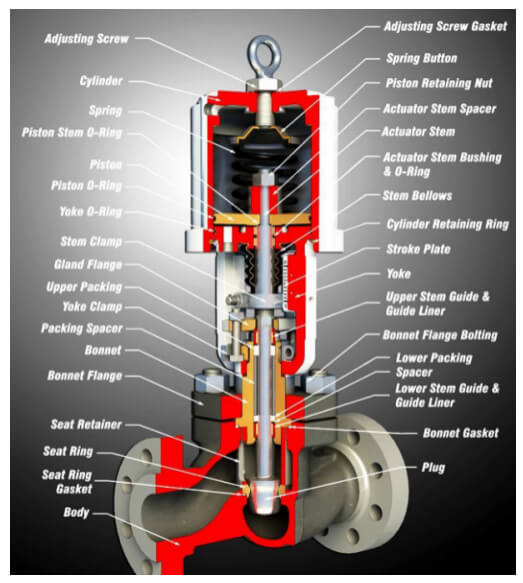

The valve part of the control valve is composed of the valve internals and the valve body. The valve internals include the valve core, the valve stem, the stuffing box the upper bonnet, etc. The stuffing box parts are used to seal the valve stem, which is prevented by elastic methods. The process medium leaks on the surface of the valve stem through reciprocating or rotating movement, which is an integral part of the valve body, and the valve stem sealing is almost always realized by using a stuffing box.

The control valve packing is the packing material of the dynamic seal, which is generally installed in the stuffing box of the upper valve cover, and its function is to prevent the leakage of the controlled medium caused by the movement of the valve stem.

Polytetrafluoroethylene (PTFE) is a polymer compound formed by polymerization of tetrafluoroethylene. It has excellent chemical stability, corrosion resistance, sealing, high lubrication and non-stickiness, electrical insulation, and good anti-aging ability.

Its corrosion resistance even exceeds that of glass and ceramics, and it has good corrosion resistance even against strong acids, strong alkalis, and strong oxidants. It is an ideal sealing material. However, its temperature resistance is poor, and PTFE begins to crack in a very small amount above 200°, it will creep under pressure and heat, which will affect the sealing performance, and it is not suitable for molten lye or fluoride.

Commonly used PTFE fillers are:

(1) PTFE forming and weaving packing:

It is made of PTFE bulk weaving and pressing. It is an open material with good flexibility, durability, good sealing effect, and easy replacement. It is the most widely used material.

(2) V-type PTFE packing:

Generally, it is made of PTFE bar by turning, and the packing structure is V-shaped. Due to the small friction coefficient of PTFE, it is lubricated when the two ends are pressed—function, good sealing performance, and so on.

The characteristics of the V-type packing ring are: under the pressure of the medium in the valve when the lip of the outer ring of the packing is opened, it is always close to the inner wall of the packing box to achieve static sealing.

The characteristics of the V-type packing ring are: under the pressure of the medium in the valve, when the lip of the outer ring of the packing is opened, it is always close to the inner wall of the packing box to achieve static sealing. Also under the action of pressure, when the lip of the packing inner ring is opened, it is always close to the valve stem to ensure dynamic sealing, so that even if the valve stem moves up and down, it can also ensure tightness.

(3) Tetrafluoro-graphite filler:

Part of glass fiber, graphite, and molybdenum disulfide are added to improve the creep resistance and thermal conductivity of PTFE, but the hardness increases, the corrosion resistance decreases, and the sealing performance decreases.

Flexible graphite material is a non-fibrous material, which removes impurities in natural flake graphite. After being treated with strong oxidizing mixed acid, it becomes graphite oxide. Graphite oxide is heated to release carbon dioxide, and its volume expands rapidly, becoming flexible graphite with loose texture, softness, and toughness. It is a material with a long life and good sealing performance.

(1) It has excellent heat resistance and cold resistance.

The physical properties of flexible graphite hardly change from the ultra-low temperature of -250°C to the high temperature of +600°C;

(2) It has excellent chemical corrosion resistance.

In addition to corrosion in strong oxidizing media such as nitric acid and concentrated sulfuric acid, flexible graphite has almost no corrosion in other acids, alkalis, and solvents;

(3) Good self-lubricating properties.

Like natural graphite, flexible graphite is easy to slide when subjected to external force, so it has self-lubrication and good sealing performance;

(4) Because of its porousness, it is loose and curled, so its resilience and flexibility are good.

When the shaft or bushing has radial circular runout due to eccentricity in manufacturing and installation, it has sufficient floating performance. Even if the graphite has cracks, it can be well sealed, so as to ensure a tight fit and prevent leakage.

(1) Filament or weave:

This packing has good elasticity and can wrap the valve stem and purify the surface of the valve stem. Braided graphite packing can overcome the leakage of other types of graphite packing due to wear, but braided graphite packing is easy to penetrate due to the voids caused by the filamentary structure.

(2) Flake graphite:

A packing ring pressed with several graphite plates, its texture is perpendicular to the surface of the valve stem, forming a square section, so the fluid is not easy to penetrate, but it also reduces the difference between the axial pressure and the radial pressure. Ratio, need to use more pressing force to seal.

(3) Curved flake graphite:

Its texture is parallel to the axial direction of the valve stem, and it is processed with several graphite flakes. Bent flake graphite is pressed at a much higher pressure than it is in operation, so it will no longer shrink in the stuffing box. At high temperature, it is known from its principle that it is easy to penetrate. However, due to its easy processing and low price, it is widely used at present.

There are various reasons for the packing leakage of the control valve in the actual use of the field. The on-site maintenance should be based on the actual use of the valve to conduct specific analysis and judgment, and then fundamentally eliminate the cause of leakage and solve potential safety hazards. According to the law of leakage, the main reasons are summarized as follows:

(1) Improper selection of packing material and type:

If tetrafluoro packing is selected in the working condition of 150℃-200℃, the packing will experience tiny creep under the critical working condition for a long time, and the sealing performance of packing will decrease due to the action of high pressure medium; Such as liquid ammonia, tar, fuel and other highly permeable media use woven packing, these conditions are affected by high temperature and high pressure media, which are prone to leakage.

(2) Improper packing installation method:

After the packing is loaded into the stuffing box, axial pressure is applied to it through the gland. Due to the plasticity of the packing, it generates radial force and is in close contact with the valve stem, such as when the packing is installed during installation. The tight loosening and uneven force make this contact very uneven, and some parts are loosely contacted or even not contacted, causing packing leakage.

(3) During the use of the control valve, there is a relative movement between the valve stem and the packing, which is called axial movement:

During the use process, with the influence of high temperature, high pressure, and highly permeable fluid medium, the control valve stuffing box is also a place where there are many leakages. The main cause of packing leakage is interface leakage, and leakage can also occur for textile packing (pressure medium leaks out along the tiny gaps between packing fibers). The interface leakage between the valve stem and the packing is caused by the gradual attenuation of the contact pressure of the packing, the aging of the packing itself, and the loss of elasticity. At this time, the pressure medium will leak out along the contact gap between the packing and the valve stem.

(4) Frequent movements of the control valve, bending of the valve stem, wear, corrosion, and deterioration of the finish cause the packing to wear and leak.

(5) The operating conditions of the control valve change.

For example, during the heating process of the device, when the control valve changes from a cold state to a hot state, the hot medium changes greatly, and the valve stem is affected by thermal expansion, so that the packing gap becomes larger. Packing leakage is serious.

(6) The packing gland is not tight, or skewed, or the control valve is installed horizontally, which will cause poor contact between the valve stem and the packing, and the gap is too large or too small.

(1) In order to make the packing convenient, chamfer the top of the stuffing box, and place a metal protection ring with an erosion-resistant gap at the bottom of the stuffing box (the contact surface with the packing cannot be inclined) to prevent the packing from being pushed out by the medium pressure. .

(2) Improve the surface accuracy and finish of the valve stem and stuffing box.

If the sum of the coefficients of friction between the various movable parts is zero, the force acting on the packing gland can be uniformly transmitted to the entire packing without any attenuation. However, the actual sum of frictional force exists and cannot be zero. The radial force acting on the packing decreases with the increase or decrease of the distance from the gland. The greater the frictional force, the greater the pressure attenuation. Once the pressure being sealed exceeds the force on the packing, it begins to leak. Therefore, the valve stem and stuffing box should not have scratches, pitting, and wear during maintenance, and the finish should be better.

(3) The selection of suitable materials must have the ability to resist temperature changes, creep resistance, relaxation resistance and oxidation resistance.

In general, tetrafluoroethylene is preferred when the conditions are met, and graphite is selected when it is not met. Mixed fillers can also be used: one is a mixture of graphite fillers and tetrafluoro fillers; the other is a mixture of O-rings and V-shaped fillers. Graphite fillers can be used for media with strong permeability.

(4) When filling the filler, it should be added one by one, and pressed one by one with a pressing tool, so that the packing can be evenly stressed. The open packing should be staggered by 90° or 120° up and down, and the number of turns of the packing should be suitable for no leakage. If the packing gland is not added, it will enter the stuffing box, which is easy to cause leakage.

(5) For the PTFE packing under the action of the spring, the gland screws should be tightened symmetrically and should not be skewed. Other types of packing need not be overtightened to prevent leakage.

(6) After the new valve or the newly overhauled control valve is put into use, the packing should be checked for leakage. If there is leakage, it should be dealt with in time to prevent the packing leakage from getting bigger and bigger.

(1) Use a 45° incision when the forming filler is cut off, and the incisions in each circle are staggered by 90° or 120° during installation.

(2) When using PTFE molding filler under high pressure, pay attention to cold flow characteristics.

(3) The flexible graphite ring is used alone, and the sealing effect is not good, so it should be used in combination with the graphite braided packing.

(4) Graphite fillers cannot be used for strong oxidants, such as concentrated sulfuric acid, concentrated nitric acid, and other media.

(5) The dimensional accuracy and surface roughness of the stuffing box, and the dimensional accuracy and surface roughness of the valve stem are the keys to affecting the sealing performance of the formed packing.